Nowadays, the material industry supports our quality of life in many ways. Amidst the rise of emerging economies and growing complexity of industrial challenges, MC's Materials Solution Group is working hard to decarbonize the industry in Japan and enhance its global competitiveness.

MC launched this new business group in the spring of 2024, as part of company's reorganization. One of the strengths of this group is employees having extensive experience within MC organizations and other companies in the materials industry.In our latest roundtable discussion, Asahi Globe+ Editor in Chief Kazuhiro Sekine speaks with some mid-career MC professionals who have made some remarkable achievements in the materials fields.

-

Tatsuhiro Nagatsuka

Business Development Division

Ecological Materials Business Department

Business Development Team / Marketing Intelligence Team -

Michiko Matsui

Metal One Corporation

Business Investment Management Department

Investment Unit / Planning Unit

*Currently on secondment from MC -

Natsumi Miki

Performance Materials Division

Petrochemicals Business Department

Materials Solution Team / Environmental Solutions Team -

Atsushi Tanaka

Business Development Division

Materials Business Transformation Department

Materials Businesses Contributing to Decarbonization

—— I'd like to begin by asking each of you what kinds of materials you're involved in.

Nagatsuka

I work in the Ecological Materials Business Department, where our two main focus areas are recycling and biomaterials, both of which are focused on lessening the environmental impact in materials businesses.

The former involves the recycling of waste. At present, most waste materials are not being recycled to remake the products they originated from, which is a problem. We're working to develop a new scheme to help rectify this and realize a circular economy.

The latter involves building a supply chain with the brand owners to use chemical products from biomaterials. To give you an example, we've been working with the apparel maker Goldwin, which handles distribution in Japan of brands like The North Face and others that we see on the outfits of prominent sports climbers for close to two years to develop a supply chain. Seven companies based in five countries were involved in the development of a supply chain for a sustainable type of polyester. Designed based on the principle of mass balance,* this polyester is made from a combination of renewable and biomaterials using carbon-capture-and-utilization (CCU) technologies, and because it represents a shift away from petrochemicals in the apparel industry, we're confident that it will help to reduce greenhouse-gas (GHG) emissions.

*A method of manufacturing that analyzes and tracks materials as they move through a supply chain. Inasmuch as it verifies that certified, sustainable materials are being used to replace those deriving from fossil fuels, its purpose is to gradually grow the ratio of those certified materials in the finished products and lend credibility to claims of their use by the manufacturers.

The CCU technologies used to make this polyester were jointly developed by a number of companies, including the MC Group company Chiyoda Corporation. So this project is a collaboration between internal and external stakeholders.

—— Ms. Miki, I understand that you're also involved in decarbonization work. Can you tell us a little bit about it?

Miki

Of course. I split my time between two teams in the Petrochemicals Business Department, which is part of our group's Performance Materials Division. We're working on business development of things like battery materials and next-generation solar cells.

MC's Mobility Group is trying to grow the market share of electric vehicles (EVs) and commercialize the secondary application of used EV batteries in fixed power stations (see the previous two Asahi Digital articles). The materials used to make lithium-ion and other batteries are being produced by a chemical manufacturer that our group has a long-standing partnership with. Demand for battery materials is expected to grow, so building an ecosystem* is also one of our aims as we work to develop new businesses.

*The term "ecosystem" typically refers to a natural environment in which plants, animals and other biological organisms interact with one another and support life. In business, the term refers to an environment cohabitated by various businesses that leverage their respective strengths to support mutual growth and development.

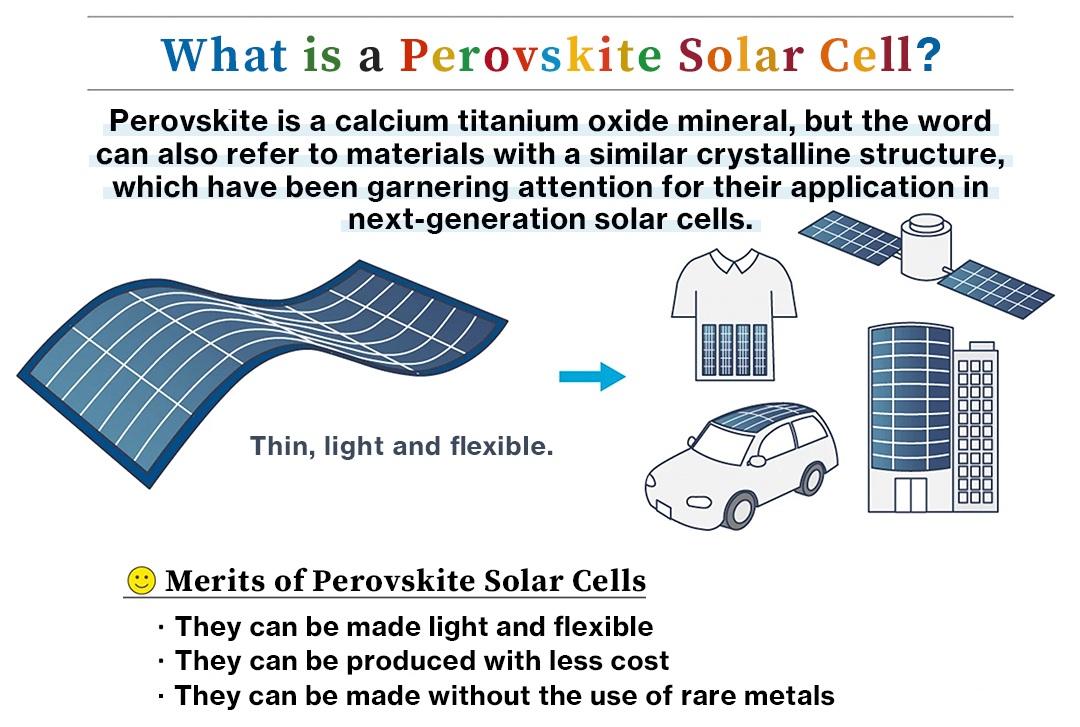

Another project we are working on is promoting societal adaptations of perovskite and other next-generation solar cells. I think a lot of people have heard of perovskite cells, because they've been in the news quite a bit lately. Traditional solar cells are made from silicon, which are very heavy, and can only be installed in certain places, but these next-gen cells are different. They're produced by coating a special substrate material to create an energy generating layer. If the substrate material is a film, the cells can be much thinner and lighter, meaning that they can be adhered to walls or even flexible surfaces.

There are some technical challenges that manufacturers must overcome before commercialization of these solar cells, so we're still a few years away. We have a number of projects underway which we hope will lead to the development of a supply chain for the raw materials and other products needed to make this happen.

Technical Solution Provider to Investment and Financing - Multi-role as a MC Pro

—— Mr. Tanaka, please tell us about your role as a tech consultant.

Tanaka Sure. I work in the Business Development Division's Materials Business Transformation Department, which dedicates to provide technical value and solution to Japan's material industry. Our objective is for Japan's material industry to remain internationally competitive. As part of that work, we teamed up with German engineering firm FEV Consulting (FEV) in 2022 to establish a joint-venture company called Beyond Materials. Our goal for this joint venture is to combine strengths of MC and FEV to connect various material industry with end users. MC's global network and business know-how in the material industry, with FEV's expertise in understanding materials, user needs, design and development capabilities in the automotive and other sectors.

—— What specifically does Beyond Materials do?

Tanaka Basically it's a tech consulting firm that specializes developing materials needed in various markets. For example, when a manufacturer is developing a new material, it's certainly possible to do so more efficiently if possible to know in advance what automakers and other end users are going to need in future. Our role is to leverage digital technologies and other tools to provide manufacturers with a wide range of end-to-end support, covering market surveys, strategy planning, product development, proof of concept experiment and marketing. Just looking at it from the perspective of materials in the automotive sector, the transition to EVs is going to drastically change how parts will be assembled, and automakers are going to have to deal with stricter regulations on the recycling of materials. We're nearing an age when automakers will be expected to use automotive's seats from old cars to make new ones, and that's going to require more advanced technologies. I think the importance of tech consulting will increase in the years ahead, as manufacturers try to accurately understand their end users' needs and challenges.

—— Ms. Matsui, you were seconded by MC to Metal One Corporation in 2023. Can you tell us a bit about your work there?

Matsui Metal One is a comprehensive steel distribution company. Its operation spans from processing, milling, sales, storage and to logistics. Unlike my three MC colleagues here today, I don't work on the front lines of any particular business. My job is in Metal One's Business Investment Management Department, and as I'm sure you can guess from the department's name, it's mainly to do with investments and planning. With respect to the former, our department considers how we can help address challenges our invested companies are facing and improve their earnings. We also consider what kinds of businesses our group should invest in, and we make our decisions based on risk return and other point of view. When requiring manegement decision, we organize points needed to be discussed and explain before decisions are to be made. Our planning work involves creating internal regulations on risk management and listing agendas for projects that are up for discussion, which is managing our company and invested companies through preparation of rule and regulations. In summary, it's about working with upper management to determine how best to run our businesses.

Strengthening our Foundation through Trading for the Next Step

—— All of you are considered "mid-career employees" at MC, meaning that you've been with the company for at least 10 years. Please tell me about how you've grown as professionals during your careers so far.

Miki

Most of our group's young employees are engaged in trading operations; in other words, buying, selling and brokering. It was the same for me when I joined MC in 2014. I spent my first three years trading industrial salt, which is an important raw material in the manufacturing of things like poly-vinyl chloride. I was responsible for selling salt produced by MC's salt operations in Mexico* to buyers in the US and Asia.

*Exportadora de Sal, S.A. de C.V. (ESSA): MC sold its entire 49% stake in this company to the Mexican government in February 2024.

In my fourth year with MC, I was dispatched to Mexico as a trainee.

My assignment was as shareholder's perspective, collaborate with the Mexican government, which at the time, MC was partnering.

I even got to experience working at the salt operation with some of MC's employees who'd been seconded to the company.

After I returned to Japan, I spent three years trading methanol. Those were valuable years because I learned a great deal about MC's mikoshi transactions, which are deals that involve speculating about future price fluctuations.

—— You later did some public relations work too. Can you tell us about that?

Miki Sure. That was in my eighth year. I wanted to be in a position where I could get a broad view of all the company's operations, and as luck would have it, I was transferred to the Corporate Communications Department's Press Release Team for two years. That was another rewarding experience, because working in that department got me thinking about the direction the MC Group was heading in, society's expectations of our company, and what kind of value we could provide in return.

—— Mr. Nagatsuka, did you also start your MC career in trading?

Nagatsuka Yes. My business life also began learning the fundamentals of trade and logistics, and experiencing global purchases and sales. My product area was plastics, and even though I was still in my early career, I was responsible for handling roughly 100,000 tons annually. After working in Tokyo head office for a while, I was seconded to Mitsubishi Corporation Plastics, where I sourced variety of materials both from domestic and international suppliers used for automotive, such as carbon fiber material used to lessen the weight of vehicles. In my seventh year with MC, I was seconded to Mitsubishi International Polymer Trade Corporation in the US. While there, I continued to work mainly in materials used for automotives, such as plastics to optical fibers. I handled more than 100 products in total.

—— I understand that you later became more engaged in managing invested companies. What was that like?

Nagatsuka Yes. After returning to Japan, I was assigned to the Strategy Planning Team in MC's former Plastics Department. I learned a lot during that assignment, including how to prepare management plans, risk management and so on for our invested companies. Furthermore, as a member of the Ecological Materials Business Department, I also worked on portfolio management (asset divestments and replacements) and gained experience with takeover bids and optimized sales of invested companies to private equity funds and other preferred buyers. The work has made me realize just how important it is for MC to continuously adapt and change. I'm now in my 14th year with the company, and I can say as a fact that MC really does equip its people with a broad range of experience. It is a true sogo shosha in that respect.

—— How about you, Ms. Matsui? Can you tell us how your career at MC has evolved thus far?

Matsui I joined the company in 2012, and I also was trained through the basics of trading. What I handled was needle coke, which is mainly used as a raw material in steel production. My responsibilities ranged from price negotiations to logistical deliveries, documents preparation, arrangements of both domestic and international shipments, after-sales services, and payment collections. In 2015, I began a five-year assignment in Beijing, which I managed marketing of steel mill products in China that had been made in South Korea. I experienced tough negotiations with the government, and I visited local mills for sales and marketing ande learned a lot in the process. That assignment was like a roller-coaster ride, because it gave me a taste of circumstances in the steel market from top to bottom.

—— After you returned to Japan, you got involved in investments. Tell us about that.

Matsui I came back to Japan during the pandemic, and I was put in charge of our group's investment projects. When I was on the business side, I was driven to sell much products at higher price as possible, and had I not been given the opportunity to see the management plans for myself, I would never have given much thought to MC's decision-making processes and other internal operations. That year taught me a lot about the company's business foundations. After that assignment, I was transferred to MC's Business Investment Management Department, where I was responsible for overseeing all of the company's investment projects. The experience I gained there has proven to be a very valuable career asset. I handled wide range of investments that differed in type to scale, and I learned up close how MC's group CEOs make their decisions.

New Value Born from Flexible and Diverse Human Resources

—— Mr. Tanaka, you did not begin your career with MC. What prompted you to leave your former company and join MC?

Tanaka I joined MC in the fall of 2023. For 13 years prior to that, I worked for a materials manufacturer. I really liked the products that company made, and I gained a lot of experience there, from sales and raw-materials sourcing, to accounting and planning. I was even posted overseas for a while. It was a very challenging work. One of the reasons I left was because the company ended up having to close its factory. We had failed to pick up the fact that some of our customers had begun making moves to start producing the materials themselves. It's important to have faith in the quality of your products and brush up on your technology, but understanding how markets are evolving and the kind of technologies that will be needed in the future is what enables manufacturers to produce, develop and sell their goods stably and efficiently. Another factor is that although Japan's materials sectors are technologically advanced, in recent years some of them have been losing their international competitiveness. On that point, I think the materials produced in Japan need to be evaluated not based on their prices per kilogram, but rather their unique properties and functions. There are elements that don't appear on spec sheets but can still set one producer apart from another, such as quality of customer care and after-sales services. When I left my last job, I wanted to help reform Japan's material industry and make it more competitive, and that's why I inquired about a position in the Business Development Division of MC's Materials Solution Group.

—— I get the impression that MC's employees are transferred between different departments in relatively short time spans. How do you all feel about that?

Miki I enjoy learning new things. My ideal timeframe in any one business would be to spend the first year grounding myself in the fundamentals, the second year putting my own ideas into action, and the third year passing along what I've learned to my successor and leaving the organization with new expertise. It's very exciting to apply the knowledge I've gained in a certain product or industry to an entirely different field. Every day, I approach my job with a sense of fulfillment. Transfers also make you realize that there's always room for improvement. For example, what's common practice where you are today might not be in practice at all where you go tomorrow. I think bringing fresh perspectives and ideas to your new assignments can only benefit the company as a whole. Matsui I think it may appear to some that internal transfers occur too frequently at MC, but even if the products we're dealing in or the size of the investments we're handling change, things like our ethics and principles in how work is done stay the same, which is why we don't find ourselves confused or uncertain about what to do. Obviously when we switch to new product areas or industries, we can gain new knowledge and experience, so I agree that it's good for our career growth. Additionally, if the company can also assign the right person to the right position, that's definitely a huge merit for the company. Nagatsuka Assigning personnel flexibly is important, but so too is workforce diversity. The Materials Solution Group is a notable case in point. It has employees from all kinds of different backgrounds, including chemicals, steel and energy. Furthermore, we've recently been bringing in more mid-career hires like Mr. Tanaka, bolstering our team with experts from industries like manufacturing, automobiles, advertising, consulting and finance. Their arrivals have injected fresh perspectives and know-how into our operations. I think it's precisely because of this professional diversity that our organization can flexibly develop so many kinds of businesses, work that even includes new challenges and asset replacements.

Built on Experience to Provide Valuable Solutions to the Materials Industry

—— What would you say to appeal against job seeking students?

Tanaka I'd start by telling them how broad an industry footprint, materials have. It's fascinating because they're the starting point of food, clothes, automobiles, construction, aircraft and just about everything else in the world. Miki The technological expertise of Japan's materials industry is still highly regarded in many fields. I think what makes our work so attractive is that we get to join forces with first-rate partners to compete in international markets. Matsui The fact that the materials industry is connected to so many other idustries means that there are a lot of business opportunities, including for our group. That makes this work very rewarding. It's also a perfect fit for job seekers who are hoping to work outside Japan one day. One of most appealing things is that we get to work in so many different places, which obviously includes different places throughout Japan as well. Nagatsuka I feel the same way, and speaking of working in different places, I've been to about ten different countries on business in the last three months alone. So I'd definitely recommend this line of work to anyone who wants to travel the world professionally. Even here in Japan, my job has taken me to some deep mountainous regions that I wouldn't have the chance to visit privately. When you work in materials, not only are you mobile, but you also get to conceive ideas that mobilize your company. I think the joy of working for MC's Materials Solution Group is that we really can do anything.

—— Let me conclude our discussion today by asking for your thoughts on the future of MC's materials businesses.

Tanaka In the materials industry, manufacturers typically have separate roles in their respective fields, like steel, plastics, synthetic fibers, and so on, but in the future, there might be some interesting opportunities for them to collaborate. For example, a broad look at the automotive supply chain would suggest that there's still new value waiting to be created. That's the perspective MC's Materials Solution Group is taking in its mission to reform Japan's materials industry and create new value. It's exciting to do influential work, and I'm looking forward to taking full advantage of MC's strengths so that we can contribute to the future of this industry. Nagatsuka Over the last year, I've met with more than 40 customers in the automotive, home electronics, retail, food, apparel and other industries. They need a wide range of materials, all of which our group deals in, and we provide them with an equally wide range of services as well. Our value spans everything from materials development to manufacturing, processing, sales, logistics, company management and consulting. Our strength is in our name, because it's not just the materials we're delivering, but the solutions as well. I hope that in the future, we'll be able to use that strength to address more of society's challenges.

- Our next article will feature the second half of the roudtable discussion with members of MC's Materials Solution Group.