MC's materials operations are handled by its Materials Solution Group. In the second of our two roundtable discussions with the group, Asahi Globe+ Editor in Chief Kazuhiro Sekine sits down with four of its young and mid-career employees to hear their thoughts on its diverse business activities. From developing cutting-edge decabonization products to growing businesses through new collaborations and providing marketing support to services that have the potential to revolutionize technological developments, MC's Materials Solution Group is taking on some bold challenges to redefine conventional practices and idealogies in Japan's materials industry.

-

Yuta Ohashi

Performance Materials Division

Semiconductor Business Department

AI & Semiconductors Solutions Team

*Currently on secondment at Preferred Computational Chemistry, Inc. -

Junki Horio

Carbon & Ceramics Division

Construction Materials Department

Domestic Business Management & Business Development Team -

Koyume Endo

Global Marketing Division

Alcohol & C1 Chemicals Marketing Department

Methanol Team -

Shuto Naruse

Business Development Division

Materials Business Transformation Department

New Business Development Team

*Currently on secondment at Toyobo MC Corporation

Functional Materials Addressing Water Shortages and Renewable Energy Growth

—— In our second roundtable discussion with members of MC's Materials Solution Group, I'm joined by four more of its professionals. I'd like to begin by asking each of you to explain the businesses you're involved in. Let's begin with Mr. Naruse, who I understand works with functional materials. Can you tell us a bit about that?

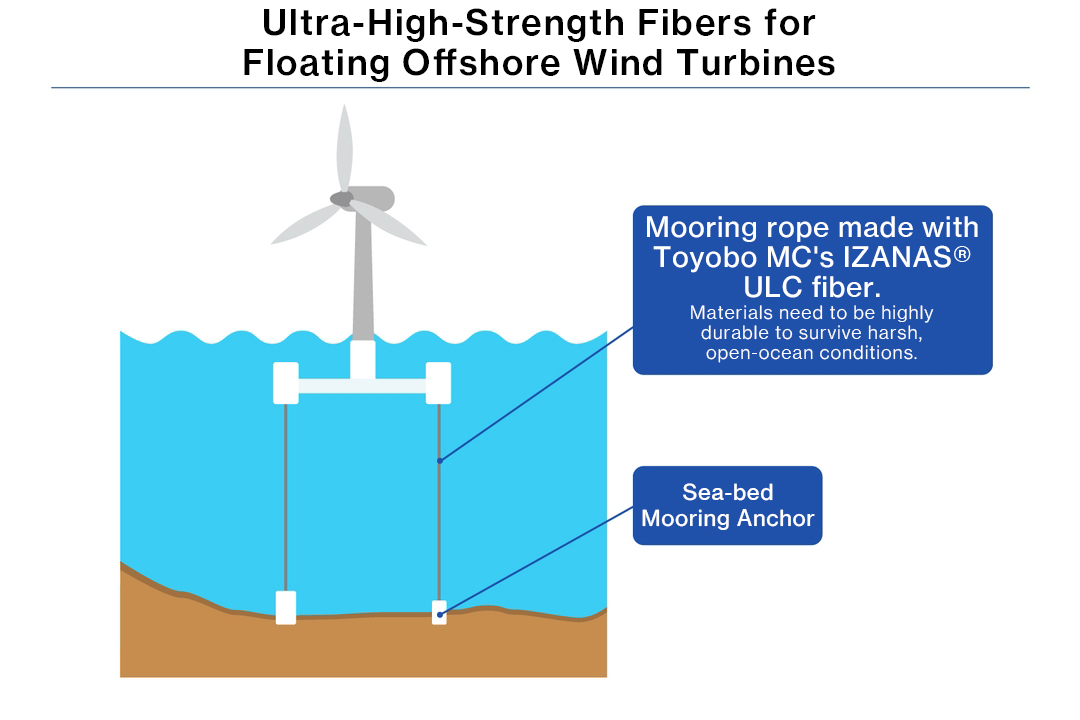

Naruse Of course. I work in the Materials Business Transformation Department, which is part of our group's Business Development Division. My department handles shareholder operations and growth support for Toyobo MC, which is a joint venture between MC and Toyobo Co., Ltd. that plans, develops, manufactures and sells functional materials. Functional materials have properties and characteristics not found in traditional materials. They provide higher performance and greater added value. For example, Toyobo MC's proprietary HOLLOSEP® water-treatment membrane is specially designed to be permeable, but only up to a certain size of the water molecules or ions. This membrane has been effectively used for many years at desalination plants in the Middle East and other regions that lack fresh water. By making high-efficacy, high-precision products like this more readily available, we can help to address water shortages around the world. Toyobo MC also produces an ultra-high-strength polyethylene fiber called IZANAS® ULC, which has been used to make the mooring lines for a floating offshore wind power generating facility. These lines need to have high strength, elasticity and durability to ensure that the turbines remain firmly anchored to the sea bed and resilient to fluctuating ocean conditions like waves, water temperature and buoyancy. An open-ocean trial of these turbines began in July 2024, and Toyobo MC has plans to expand its production facilities for this fiber to help grow the development of similar offshore wind farms.

The company is also developing and manufacturing highly functional fibers, adhesives, paint raw materials, and other products that are vital to lightening and electrifying automobiles.

—— It would certainly appear that highly functional, high-added-value materials are helping to solve a lot of problems. What are expected against MC in all of this?

Naruse Toyobo MC's strength is that it's a tag-team operation between a manufacturer and a sogo shosha. By combining Toyobo's advanced tech capabilities with MC's industry expertise, global network and management know-how, our joint venture is endeavoring to create new businesses and products. For example, it's not easy for materials makers to accurately grasp the diverse needs of end users. It's an ongoing process of trial and error, but we're leveraging MC's network to develop and manufacture the kinds of products that are most sought after by customers. We also recognize the urgent need for the materials industry to adapt to the rapid changes that are underway in today's world, such as pushes to decarbonize and reduce weight in conjunction with the spread of electric vehicles. To that end, we've been discussing the formation of joint business models and alliances, and demonstrating our new-business-creation capabilities. We're looking forward to continuing our efforts to grow Toyobo MC's functional materials businesses, and by extension, helping to make all of Japan's materials providers more internationally competitive.

Cutting-edge Construction Material "Takecite" Made from Recycled Sludge

—— Mr. Horio, I understand that you're working with a construction material that's made from industrial waste. Can you tell us a bit about that?

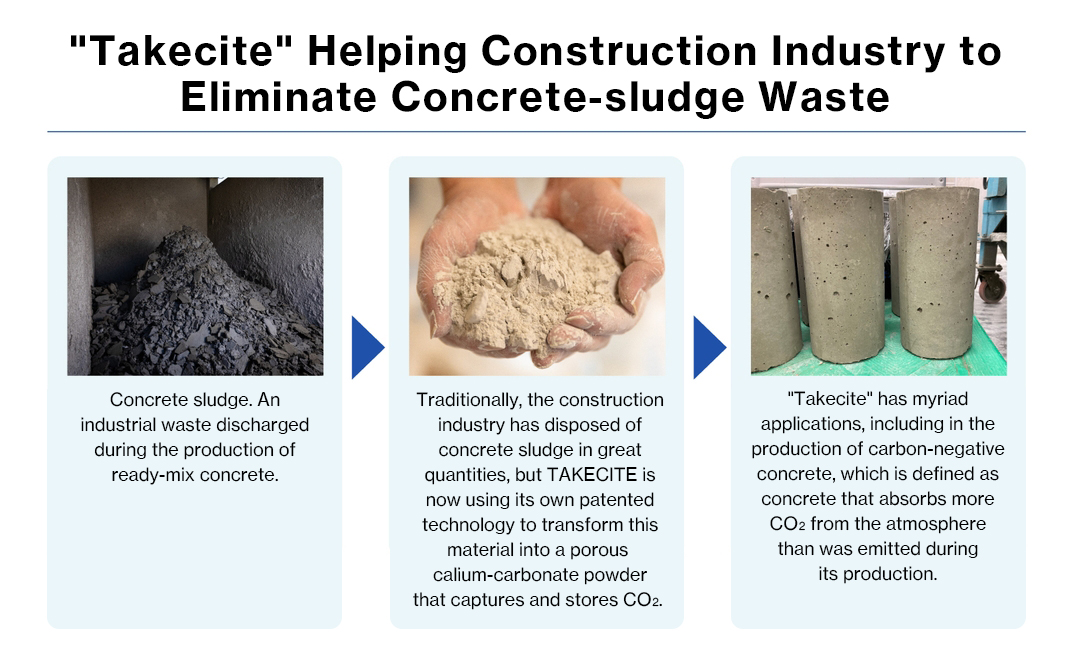

Horio Sure. I work in the Construction Materials Department, which is part of our group's Carbon & Ceramics Division. We handle the business of a venture-capital company called TAKECITE, which is headquartered in Shizuoka. It recycles concrete sludge, a waste product from the production of ready-mix concrete, into a decarbonized carbon material. About 2-3% of the ready-mix concrete that's shipped ends up returning to the plants as waste. Because it's burdensome for construction companies to have to keep contacting the concrete suppliers and ordering more, it's common practice in the construction industry to account for the waste by ordering a surplus amount. This waste that's returned to the concrete makers, concrete sludge, is composed of the same sediments and sands as cement, but there aren't many ways to effectively reuse it. So in most cases, it's simply disposed of as industrial waste. Cement production emits CO2, so this is a big problem. Transporting concrete sludge also produces CO2 emissions, and then there's the costs associated with its disposal. These are significant challenges faced by the construction industry. The company TAKECITE uses this concrete sludge to make its namesake product "Takecite," which is a carbon powder produced with CCU technology. That's what's special about this powder. As it's being manufactured, it actually captures and stores CO2 from the air.

—— Can you explain in more detail how "Takecite" absorbs CO2?

Horio One of the distinguishing properties of ready-mix concrete is that it has always absorbed and stored atmospheric CO2 during its drying process, but TAKECITE's proprietary technology increases CO2 capture and storage by producing this renewable, low-carbon building material. Data from trials of the technology confirmed that each ton of "Takecite" produced can trap between 100 and 200 kilograms of CO2 from the atmosphere. "Takecite" could become an alternative to a number of construction materials, including ready-mix concrete and cement, a raw material used to strengthen foundation integrity, and calcium carbonate, which is used to produce plastics and synthetic wood. Work is now underway to build a new "Takecite" manufacturing facility and otherwise prepare to ramp up production and commence full-scale sales operations.

—— Reusing waste to promote decarbonization seems a truly cutting-edge business.

Horio Absolutely. Because "Takecite" recycles something that would otherwise be thrown away, it will help us to realize a circular economy. Furthermore, in addition to capturing and storing atmospheric CO2 during its production, it can replace other products whose production does the opposite (i.e. generate huge CO2 emissions). I think it really is a cutting-edge product, and it should force a change in what has become conventional thinking in the construction industry, namely that wasting concrete sludge is unavoidable and that cement production always emits CO2. I'd like us to help create a new sense of values in this industry that's more in keeping with the times.

Rewriting the Future of Materials Development

Global Applications of a Made-in-Japan Simulator

—— Mr. Ohashi, you're currently working in a company that provides new-materials-development in a cloud-service environment. Tell us about that.

Ohashi Sure. Right now I'm on secondment at Preferred Computational Chemistry, Inc. (PFCC), a company with which the Semiconductor Business Department of our group's Performance Materials Division formed a business-and-capital alliance in June of this year. PFCC was established in 2021 as a joint venture between Preferred Networks Inc. (PFC) and Eneos Corporation (Eneos). Its mission is to support sales of the universal atomistic simulator MatlantisTM (Matlantis), which was co-developed by PFC and Eneos. Calculations for atomic-level simulations are complex and time consuming, but by taking advantage of AI technology, Matlantis can perform accurate, high-speed calculations that conventional physics simulators are incapable of. It has been lauded for its usefulness in discovering and developing new materials, and as of September 2024, more than 90 entities have used it, including both business enterprises and the research arms of universities and other organizations. While most of its applications have been here in Japan, it has attracted interest in other countries as well.

—— Can you explain in a bit more detail how Matlantis is useful?

Ohashi The global push to decarbonize has elevated the need for private-enterprise research institutes and academia to develop new materials. Examples include green hydrogen (i.e. that derived from renewables), catalysts to produce CO2-feedstock synthetic fuels, and new battery materials designed to improve their power-generation efficiency and durability. Furthermore, there's a great need in many fields to replace materials that are either harmful to the natural environment or a drain on scarce resources. Typically, the time frames for developing new materials are measured in years or longer. This is partly due to the planning and R&D time required to establish themes and identify candidate materials, but it's also because of considerations that have to be given to synthesis, reaction and other test conditions, as well as all of the procedures that have to be followed up to and including production. Products' lifecycles are the times between their initial releases and eventual discontinuances, and those lifecycles can shorten. Markets can also change quite rapidly. Developers must prepare for those possibilities, so simulators have been considered because they're capable of performing many tests over a brief period of time; however material-behavior simulations require atomic-level calculations, which are extremely complex. A single simulation can take many hours, so up to now simulators haven't been a realistic option for material discoveries. The process of developing new materials has always relied on real-world experimentation and intuition. Matlantis is a game changer though because its' a deep-learning model that probes big data from conventional simulator calculations. Its simulations are based on deductions from test-subject calculations. It can calculate tens of thousands of times faster than conventional simulators, and in some cases it has taken just a week to complete calculations that would have otherwise taken 20 years. Matlantis has numerous industry applications, and it already has a proven track record in simulating behaviors of materials for the production of semiconductors, chemicals, electrical and electronic components, ceramics, battery materials, cataylsts, and many other products.

—— What's MC's involvement in this business?

Ohashi As I mentioned, Matlantis has gained a lot of interest and is being used by more and more entities, primarily here in Japan. PFCC is now focused on rolling this service out to more users around the world. MC is keen to leverage its broad industry know-how, international network and management expertise to assist PFCC's global growth. Helping to promote societal adaptations of a service that is so technologically advanced is extremely rewarding, and I think this is certainly another business that will enable MC to create new value in the materials industry.

Lessons Learned from Trade, the Original Shosha Business

—— Ms. Endo, please tell us about your work in methanol trading.

Endo Methanol is a highly versatile chemical, the global demand for which is in excess of 100 million tons per year. It has widespread applications. As a raw material, it's used to make plastics and silicon, and it can also be used as an automobile fuel (when mixed with gasoline) or an alternative to the heavy oil (bunker fuel) in the shipping industry. Natural gas, coal and a variety of other feedstocks can be used to make methanol, so it's produced all over the world. MC has methanol-producing business investments in Venezuela, Trinidad and Tobago, and Saudi Arabia, but we also work with third parties to source the fuel from elsewhere and sell it to buyers in Western countries, Asia, and other parts of the world. These procurement and sales operations require close collaboration with the locally hired employees at MC's regional offices.

—— What do you find most rewarding about trading work?

Endo The sogo shosha started in trade, and I feel a great sense of responsibility doing this work because of how important its roles are. It's rewarding to know that I'm helping to rectify supply-and-demand imbalances by meeting regional, timing and volume related needs. Another aspect of this work that really appeals to me is the fact that each of our decisions has such a dynamic impact on the movement of huge amounts of money and products. I take part in a lot of tense negotiations on pricing, both in and outside Japan, but even after those talks are concluded, unpredictable events are constantly taking place. Will a vessel suffer an engine breakdown? Will there be a hurricane that grounds everything to a halt? Dealing with those sorts of things is a year-long challenge, and when they happen, I have to work with the shipping companies, terminal operators and sellers to overcome them. It's very challenging work, but it gives me a great sense of accomplishment when things work out. More young employees are assigned to trading jobs in the Materials Solution Group than in any of MC's other business groups. In addition to all of the experience and know-how we gain from those jobs, they teach us how to keep businesses running smoothly and convince our trade partners to accept our positions. All of the keen insight I've gained from trade has proven very beneficial in my later career.

The Fascinating Universality of Materials Businesses

—— Doing business with international clients must be both rewarding and challenging.

Naruse One of the projects I'm involved in is a partnership between three companies, including a non-Japanese manufacturer. When you have meetings between people who hail from different countries and businesses, you're bound to have your fair share of disagreements. Those are the times when I try hardest to meet my counterparts outside the conference room, for example at lunch or dinner, so that we can really get to know and understand one another. I think more casual interactions like that are every bit as likely to lead to solutions. Doing business with people who have different values and ways of thinking is both the hardest and most enjoyable part of my job. Endo I feel the same way. This year I've been on business trips to more than 15 countries, and some of the meetings I've attended during those trips have gotten quite heated. One thing that never changes though, is that no matter how tense things are at the office, we always get together that same evening to enjoy the local food and drink, and we always leave one another with hugs and handshakes. Such moments often remind me of MC's stance of prioritizing the building of long-term partnerships over the pursuit of near-term profits. Last winter, I just happened to be in Europe when a shipment I had arranged from Latin America was docking at the port near where I was staying, so I got to see with my own eyes this huge vessel as it came in. It's difficult to put in words that sense of scale, a world that's unimaginable from our desks here in Marunouchi. I was really moved by the sight, and I was even given a tour of the ship's engine and motor rooms. I had a wonderful conversation with its Indian captain who served us with hot chai tea. It goes without saying really, but on every single business deal there are many pros working behind the scenes. That experience in Europe brought that home to me again, and I felt full of gratitude. It made me even more determined to do everything I can to meet our businesss partners' expectations. I remember another time when I was in Latin America. An employee of one of our business investments there told me that his job at that company was the reason he was able to pay for his children's education. Our businesses do indeed contribute to societies all over the world, and that's another reason they're so rewarding and enjoyable.

—— How would you describe your group's distinguishing characteristics? What separates it from MC's other business groups?

Horio I think most of your readers are probably familiar with some of MC's businesses, such as its automobile, food and convenience-store operations, but I doubt many of them are aware of materials businesses and the impact those have on their day-to-day lives. Much of what we touch and use has a material connection. For example, if you took a snapshot of any scene, whether it be indoors or outdoors, I think that when you looked at it you'd spot many materials and products that MC's Materials Solution Group handles. Personally, I find the sheer breadth of that value chain overwhelming, and I almost feel that our group is a "sogo shosha" in and of itself. It's a really interesting group.

No Fear of Failure

What Gives MC's Young Employees the Courage to Take on Challenges?

—— Listening to all of you today, I get the sense that your group's employees are given a lot of discretion, even from a young age. Please tell me about some of the personal initiatives you're taking, and the support you're getting from those around you.

Endo Before I joined MC, I figured that at first I'd be put in a supportive position, but that wasn't the case. Right from year one, I was put in charge of managing domestic shipping. My superiors simply assigned me to a ship, told me to do a good job and left every aspect of the work to me. I was also the main negotiator in contracts, meaning that at times I had to negotiate directly with shipping company veterans or the presidents of companies that had offices all over Japan. Sometimes I felt intimidated by my counterparts' advanced experience or ages, but I kept reminding myself that I was a professional in the methanol trade, and that it was up to me to fulfill that responsibility. That approach helped to steel and prepare me for the challenges ahead. I'm now in my fourth year with MC, and I'm being entrusted with larger and larger deals. I can't help but feel motivated to come to work every day. Perhaps it's also important to have the courage to take on any challenge, because it can lead to opportunities.

—— I can understand why you'd be happy to have such a large amount of responsibility, but don't you also worry about failing?

Endo Of course. There are times when I wonder whether I'm really qualified to do what's being asked of me, but my senior colleagues and superiors always remind me that I have their support, and they encourage me to just do my best. I know that I can always rely on their support. Whenever I'm having trouble, they take the time to answer my questions and advise me, and when I don't get good results, they give me the proper guidance to help me improve next time. Our team has a relaxed atmosphere that encourages everyone to speak freely with one another regardless of experience or seniority, and I feel lucky to be a part of it.

—— Mr. Ohashi, I hear that you helped launch an in-house venture. Can you tell us about that?

Ohashi Sure. In my third year with MC, we set up a truck-dispatch matching service to help improve liquid-chemicals logistics. The idea came to me roughly one year after I joined the company. I was overseeing methanol sales in Japan, and due to a driver shortage, it was getting difficult to arrange for the product's transport. I still didn't know much about the industry, nor did I have a fully formed solution in mind, but I did recognize that the problem could be a business opportunity for MC, so I kept bringing it up with my team members and sharing my thoughts with them. My boss at the time showed a particular interest, and he spoke to me about it every week. After a few months of encouraging feedback, I had a plan in place and we were able to turn it into a business. We're currently revising the model to match the changing business climate, but the whole experience has taught me quite a bit, including the importance of coming forward with ideas and having the humility to listen to others' opinions. It's not a good thing to keep quiet just because we're worried about our lack of experience or are afraid of failing. I'm also grateful to my team members and my boss for taking me seriously and hearing my ideas.

—— Mr. Horio, you were transferred to a job that you had been keen to try. Tell us about that experience.

Horio I used to manage a company in North America that manufactures and sells cement and ready-mix concrete, and I was involved in a business that had a 40% market share for the latter of those products in Southern California. Getting to work on such a large project was very satisfying, but I started feeling that for my next job, I'd like to have a position that was more on the ground, closer to where the action was. As luck would have it, that opportunity came about in 2023, when I was put in charge of operations at TAKECITE. Right now we're preparing to open a new factory in February 2025, so I'm in talks with the company's president about pretty much all of the decisions that need to be made. For example, we have to figure out where to position all of the equipment, where to get funding, who to sell the product to, and so on. This business operates at a totally different speed and scale than that of my previous job, which was worth tens of billions. TAKECITE is a venture capital startup, meaning that we're building the business from scratch, but it's every bit as fascinating as my previous work. Also, even though it's a small-scale enterprise, I'm confident that TAKECITE can help change society for the better, and that makes every day enjoyable.

Uniting and Revolutionizing Japanese Materials Industry

—— I'd like to conclude our discussion by asking each of you about your professional ambitions and outlook for the future.

Horio My goal for now is to help expand TAKECITE's business beyond Shizuoka to other parts of Japan. Further down the line, I hope that we'll be able to extend the company's reach to North America and other international markets. MC has two missions, one being to simultaneously realize economic, societal and environmental value, and the other being to grow sustainably as a business enterprise. I think the work being done by TAKECITE ties in perfectly with our missons. Regardless of scale, it's a value-added business, and I'm keen to stay engaged in it. Endo Being on the front lines of MC's trading activities, I'm privvy to certain know-how and insight on global trends. My goal is to apply that intelligence to the company's business developments and investments. That's my role, and I am determined to do it to the best of my ability. I'm also hoping to one day work in human resources, public relations, or other corporate roles that provide a broad overview of MC's companywide operations. Ohashi My thoughts and aspirations haven't changed since I began working at MC. The sogo shosha not only have unique ways of identifying industry challenges, but they also have unique approaches to addressing those challenges. I want to help leverage that strength to better industries and societies. My more immediate goals are to promote the digital transformation of work to develop new materials and assist society with their practical applications. Naruse I began working for a materials manufacturer when I graduated from university, so I didn't join MC until later in my career, in 2023. MC's position and involvement in the materials industry are very different from those of my previous employer, but my own goals of reforming that industry here in Japan and making it more globally competitive will never change. Japan's materials manufacturers are facing a lot of challenges, particularly with respect to sustainability, logistics and global sales. Those are urgent issues, and we can't just assume the manufacturers will be able to come up with solutions on their own. I'd like us to take a more collaborative approach that engages different companies and covers the full breadth of the materials industry. I think it would be great if we could leverage MC's network, industry acumen, and powers of business conception to take Japanese materials to new heights.