Connecting to the future:MC's Next-Generation Energy Business Group A New Organization Dedicated to Decarbonization

The Present and Future of Next-generation Energy vol.1

MC's Next-Generation Energy Business Group

A New Organization Dedicated to Decarbonization

Since Russia invaded Ukraine, the global energy situation has been in a state of confusion, which has only added impetus to MC's push to promote energy transformations (EX). In April 2023, the company set up its Next-Generation Energy Business Group, an internal organization dedicated to the identification and practical application of clean technologies, and the forging of next-generation energy supply chains. MC has used this new organization to centrally manage all of its decarbonization-related professionals and projects, which had previously been scattered throughout its numerous, industry-specific business groups. But what exactly are the goals of this new organization, and why is it so important for MC, a company engaged in so many diverse industries, to focus on EX?

Having announced its intention to be a carbon-neutral enterprise by the year 2050, MC is making some bold moves and decisions. Part 1 of our series examines the current state of the company's operations and the challenges it is facing, with a particular focus on its decarbonization initiatives and EX strategies.

Carbon-neutral by 2050 - Japan's Progress Thus Far

There are more than 140 countries and regions around the world that have pledged to be carbon neutral by the year 2050. Japan is one of those countries, but how has it been doing so far?

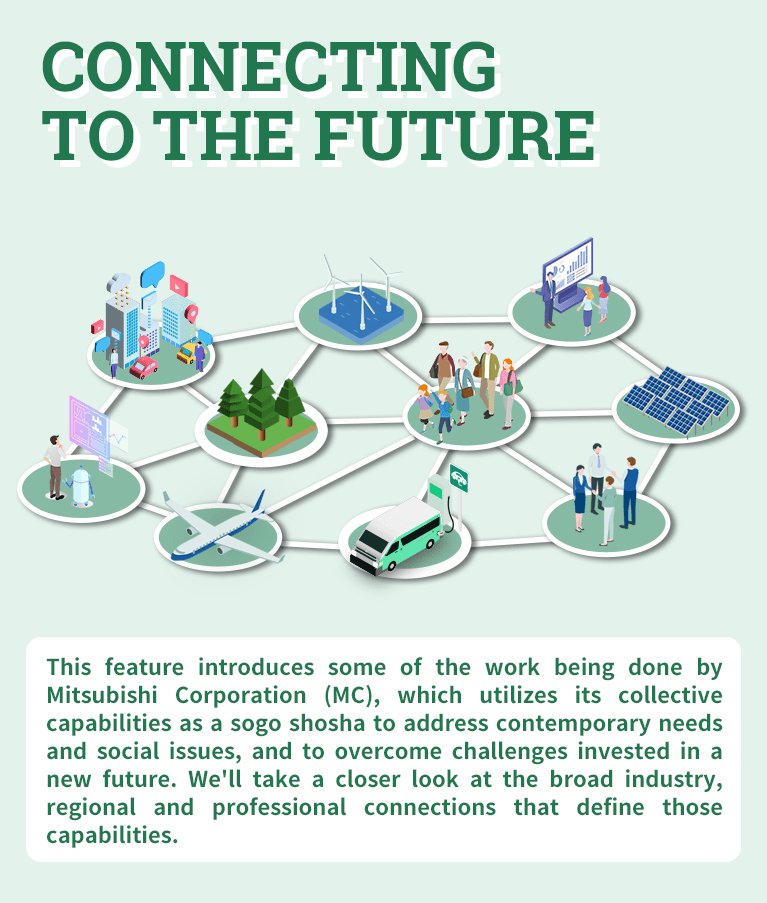

According to its Ministry of the Environment and National Institute for Environmental Studies, Japan's gross greenhouse-gas (GHG) emissions in fiscal year 2021 were 1.17 billion tons (CO2 equivalent), while its net GHG emissions (after subtracting its sequestered GHG) were 1.122 billion tons. Due in part to increased energy consumption driven by the post-pandemic economic recovery, Japan does not appear to be on pace to achieve its reduction targets. If the country has any hope of meeting its 2050 goal, then this truly is a case of "now or never."

How Do We Become a "Carbon Neutral" Country?

What measures must be taken to reduce Japan's total GHG emissions to zero?

Some 84% of the country's GHG emissions are energy-derived CO2 emissions. Of those, approximately 40% come from power generation and approximately 60% come from other heat-and-fuel-use sources, including industry, transportation, and household consumption. To get these CO2 emissions close to zero, it is essential that we not only do more to both conserve energy and use it more efficiently, but also develop and commercialize clean (carbon-zero) technologies.

We must begin by decarbonizing the power-generation sector, or in other words, coming up with the most eco-friendly means possible of generating electricity. Specifically, this means transitioning from oil, coal and other fossil fuels to renewables, hydrogen and other green alternatives.

Around the world, the call is growing to decarbonize just about everything that has up to now been driven by fossil fuels, and as is evidenced by accelerating moves in the auto sector to switch from gasoline-powered vehicles to electric and fuel-cell vehicles, progress is being made to answer that call. Besides electrification and hydrogenation, other low-carbon alternatives include e-methane (synthetic methane produced with CO2 and hydrogen), e-fuels, and biomass fuels.

Even if such switches are made, to get to net-zero we still need to offset the CO2 we produce by sequestering (i.e. capturing and storing) an equivalent amount. Forestation is often cited as the best way of doing this, but in recent years some other methods have been capturing our attention, such as CCUS (carbon capture, utilization and storage) and DAC (direct air-capture) systems.

Current Situation and Challenges in Next-generation Energy

Success in decarbonization will demand many different approaches, all taken simultaneously. Here we take a look at some of those involving next-generation energies and technologies.

SAF | Efforts to Commercialize Domestically Produced Sustainable Aviation Fuels

Aviation is one of the more challenging industries when it comes to transitioning to things like electricity and hydrogen, however there is growing interest throughout the industry (both in Japan and around the world) to adopt sustainable aviation fuels (SAFs).

SAFs are biofuels made from used cooking oils, animal fats, alcohols, such as ethanol derived from vegetable, hydrogen and other feedstocks, oils and so on. By mixing them with traditional jet fuel, they can drastically cut an aircraft's CO2 emissions. Furthermore, they are compatible with existing engines and other aviation equipment and infrastructure.

The background behind the aviation industry's acceleration towwards decarbonization efforts is the CORSIA framework adopted by the International Civil Aviation Organization. The original aims of CORSIA, which stands for Carbon Offsetting and Reduction Scheme for International Aviation, were to improve the global industry's fuel efficiency by an average of 2% per year and keep its GHG emissions from increasing beyond 2020 levels. Countries and regions around the world have set their own targets to adopt SAFs. For example, the US and EU are aiming to replace for 100% and 70% of their respective total aviation fuel usages with SAF by the year 2050, while Japan is shooting for 10% of its total aviation fuel usage by the year 2030.

In 2020, the production volume of SAF was less than 1% of the world's aviation fuel usage, but with their demand expected to grow rapidly in the years ahead, for the sake of stability and competitive pricing, the commercialization of domestically produced SAF is desired in Japan.

Furthermore, we will likely see greater impetus to forge SAF supply chains in the near future, including advances in production technologies, lower manufacturing costs, and methods of sourcing raw materials that are more conducive to large-scale increases in production.

Hydrogen | Transporation Sector Key to Growth with Clean-tech Trump Card

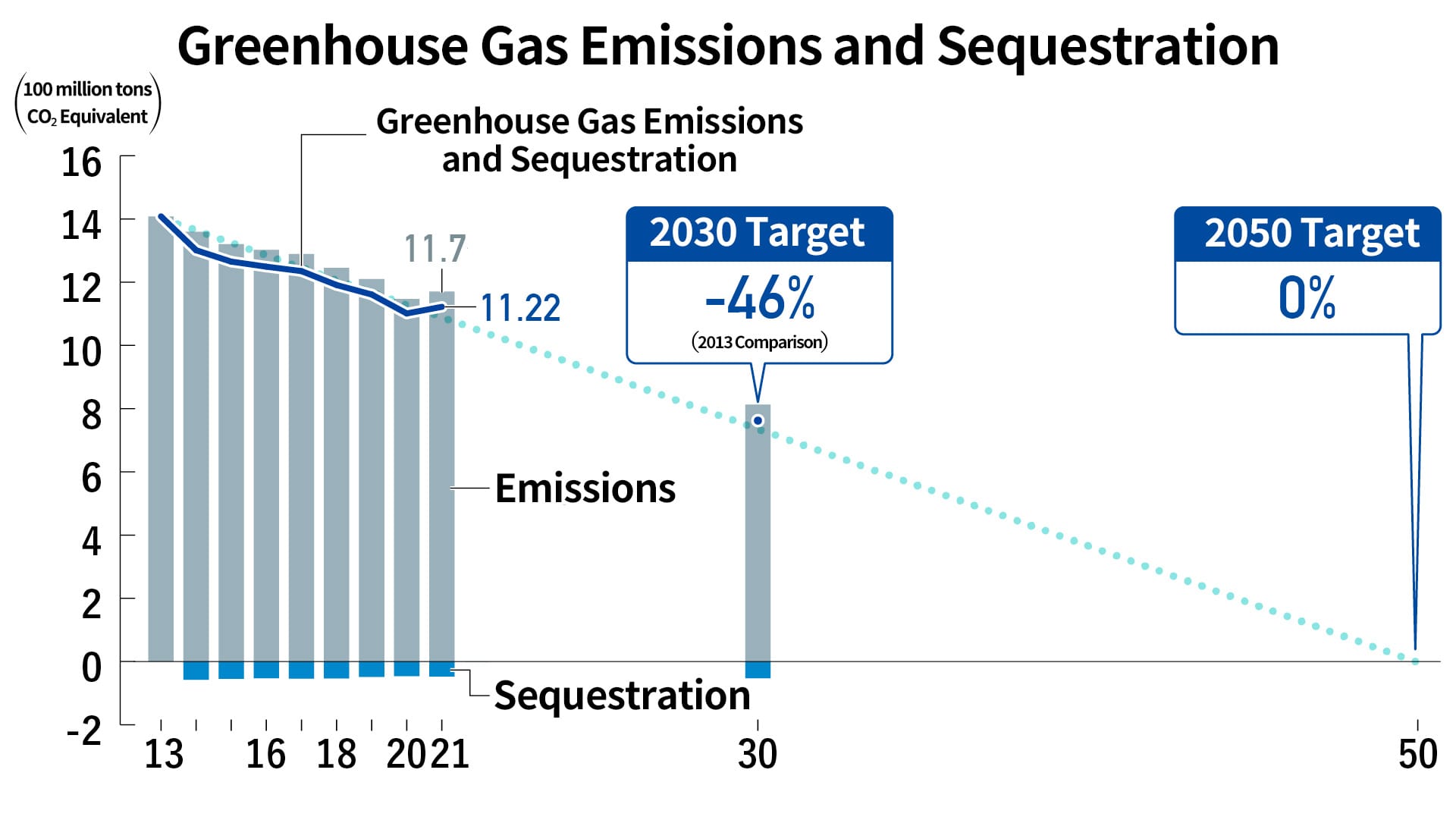

Hydrogen plays a central role in next-generation energy, and there are great expectations surrounding its future and potential applications.

In addition to emitting no CO2 when used as a fuel or power-generation feedstock, hydrogen has many benefits as a source of energy. For example, it can be produced from a wide variety of resources, such as water (through water elecrolysis), natural gas and other fossil fuels (through reforming) and even sewage sludge and plastic waste (the techniques for which are currently being researched). It also has numerous applications, examples being in fuel cells to generate electricity, heat, and power, as a raw material in the manufacturing and chemicals industries, and (as mentioned) as a feedstock for power plants.

Process of making carbon-neutral methane (main component of natural gas) from green hydrogen and captured CO2. If e-methane can be used for city gas production, then existing LNG and town-gas infrastructure can also be used in the future.

However, many challenges must be overcome before hydrogen can be used more widely, such as its high manufacturing and transportation costs, the relative scarcity of hydrogen stations and its other related infrastructure, and the need for new ways to transport it.

CCUS | Helping Japan Reach its "Net-zero" Goal

Even if progress is made in electrification, hydrogen, SAFs and all other approaches to decarbonization, they will only go so far in reducing our carbon footprint. There are certain areas where using new technologies is prohibitively difficult or costly.

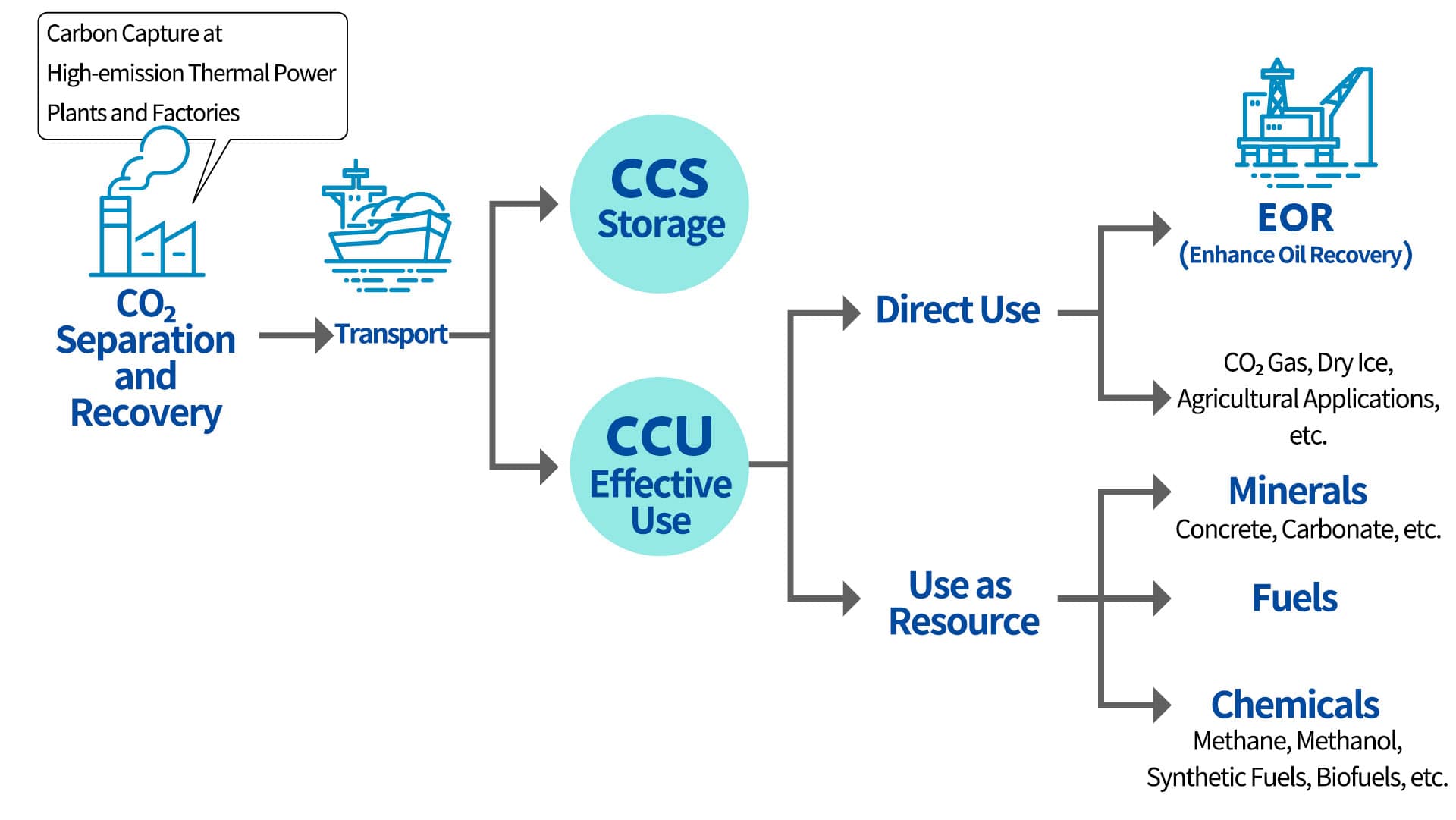

One field of technologies that is being heralded as revolutionary is carbon capture, utilization and storage (CCUS).

First parts are separating and capturing CO2 from the exhaust gases emitted by thermal power plants, factories and other industrial sites. Other parts (CCS) then store the CO2 in deep geological formations such as depleted oil or gas fields, and still other parts (CCU) are designed to effectively utilize the captured CO2. For example, it can be used to make things like concrete, biofuels, chemicals, and CO2 gas, or to increase oil production by pressure pumping it into oil fields.

But before society can use CCUS systems on a broader scale, their costs must be brought down and value chains constructed, both here in Japan and around the world.

Ammonia | Forging a Supply Chain to Span Myriad Applications

Ammonia is often used as a raw material in the production of fertilizers and chemicals, but because it does not emit CO2 when burned, in recent years it has also been attracting interest in the energy sector, where it can be used directly as a power-generation feedstock or indirectly as a hydrogen carrier.

As mentioned, the key next-generation, carbon-zero energy source is hydrogen, but its low molecular weight means that it can easily escape from tanks and pipelines. Its other characteristics (such as its tendency to burn very quickly) also make it extremely difficult to transport, store and use. This is where so-called "hydrogen carriers" come into play. These organic compounds can transport and store atoms of hydrogen more efficiently by absorbing and releasing it through chemical reactions.

Ammonia (NH3) is synthesized by reacting atmospheric nitrogen (N) and hydrogen (H). In addition to preventing CO2 emissions during combustion (when used as an energy feedstock), ammonia's physical properties are such that it can absorb a high concentration of hydrogen, even compared to other carriers. Furthermore, because it has long been commercially traded and used, it is compatible with existing merchant vessels, tanks and other infrastructure, plus the technologies to handle it safely and securely are already in place.

On the other hand, the lack of an adequate supply structure remains a concern. At present, Japan consumes roughly one million tons of ammonia per year, but its government anticipates domestic demand to grow to three million tons by 2030 and 30 million tons by 2050. Expanding the ammonia supply chain is therefore an urgent matter, both at home and abroad.

The Next-Generation Energy Business Group: Balancing Decarbonization and Supply Stability

The path to carbon neutral society must be paved with concepts that transcend industries and organizations. MC has always created projects that necessitate engagement and cooperation by its different business groups, and emphasized energy transformations. To strengthen this corporate culture, MC launched its Next-Generation Energy Business Group this past spring, assigning to it more than 260 of the company's employees.

The group is comprised of eight departments and offices. The "Biofuel & E-fuel Business Department" is tasked with developing SAFs and other next-generation fuels for transportation. The "Hydrogen Infrastructure Development Department"is responsible for forging hydrogen supply chains, the "Hydrogen Business Development Office" for e-methane applications, and the "Carbon Management Office" for developing businesses associated with carbon-credit schemes. The aim of the "New Power Generation Fuels Business Department" is to identify practical adaptations for ammonia and other fuels, while the "Refinery Business Department" is endeavoring to leverage the company's oil-refining operatons to solve problems hampering our transition to carbon-neutral societies and otherwise improve our quality of life.

Applying MC's Collective Capabilities to Help Decarbonize Our World

Why are MC getting involved in EX and what are their strengths there? One answer is their far-reaching industry connections. They have the power to link new technologies with hidden potential to those who may even be yet to realize their need for them. Some hurdles can be too high to clear with just one kind of technology, but in such cases, MC can lower those hurdles by augmenting that technology with other technologies or operations. The ability to conceive flexible solutions is a unique trait shared by Japan's general trading companies.

In truth, CCU technologies are already being used in a number of industries, including fuels, construction and synthetic fibers. Partnerships are also being formed in other industries like food, fertilizer, and animal feed to source the raw materials for SAF production.

MC's Next-Generation Energy Business Group has given it the means to cover the full breadth of energy value chains, from upstream to downstream operations. For example, it has enabled a single organization to oversee everything from the production, shipping and storage of hydrogen from other parts of the world, to its end use in a fuel-cell powered forklift here in Japan.

By balancing decarbonization with energy stability, MC is doing its part to help realize a carbon-neutral society and create a new and brighter future. More challenges await this company, but it looks certain to both embrace those challenges and accelerate efforts to meet them.

- Look out for part 2 of our series, which will feature a roundtable discussion by employees from MC's Next-Generation Energy Business Group. They will give us a more detailed overview of MC's projects and share their thoughts on what the future has in store for the company.

-

The Present and Future of Next-generation Energy vol.1

MC's Next-Generation Energy Business Group A New Organization Dedicated to Decarbonization -

The Present and Future of Next-generation Energy vol.2

Leveraging Cross-industry Connections and Know-how to Advance Societal Adaptations of Next-generation Energy -

The Present and Future of Next-generation Energy vol.3

Innovation Born of Integration Sharing the Conviction to Create the Future of Energy