Introduction to the Compact LNG Filling Facilities for LNG Trucks in Hokkaido

News & Events

-

Demonstration project by the Ministry of the Environment completed; Mitsubishi Corporation and Air Water Inc. to continue the project in FY2025 with partners.

-

Operations suspended at Ishikari filling station.

-

Conducted the 7th Liquefied Bio Methane mixing to LNG at Tomakomai filling facility.

-

Achieved cumulative 3,000 times LNG fill-ups(Approx. 470 tons of LNG) at Tomakomai and Ishikari filling facilities.

-

Air Water Specialized Transportation Inc. commenced operation of an LNG tractor head manufactured by Volvo Trucks.

-

Achieved cumulative 2,500 times LNG fill-ups(Approx.390 tons of LNG) at Tomakomai and Ishikari filling facilities.

-

Achieved cumulative 2,000 times LNG fill-ups(Approx.320 tons of LNG) at Tomakomai and Ishikari filling facilities.

-

Conducted the 6th Liquefied Bio Methane mixing to LNG at Tomakomai filling facility.

-

Achieved cumulative 1,500 times LNG fill-ups(Approx.240 tons of LNG) at Tomakomai and Ishikari filling facilities on August 18, 2023.

-

Conducted the 5th Liquefied Bio Methane mixing to LNG at Tomakomai filling facility.

-

Achieved cumulative 1,000 times LNG fill-ups(Approx. 160 tons of LNG) at Tomakomai and Ishikari filling facilities on April 12, 2023.

-

Obtained approval for 2 years extension of the trial period by the Ministry of the Environment in April, 2023.

-

Conducted the 4th Liquefied Bio Methane mixing to LNG at Tomakomai filling facility.

-

Conducted the 3rd Liquefied Bio Methane mixing to LNG at Tomakomai filling facility.

-

Conducted the 2nd Liquefied Bio Methane mixing to LNG at Tomakomai filling facility.

-

Achieved a cumulative 100 tons of LNG fill-ups at both of the Tomakomai and Ishikari filling facilities on Dec.15, 2022.

-

Broadcasted a news and published an article about the 1st mixed trial of liquefied bio-methane(LBM), purified from livestock manure-based biogas and trial operation of an LNG truck in the Japan Broadcasting Corporation (NHK) Sapporo on Nov.19, 2022.

-

Published an article about the 1st trial of mixed liquefied bio-methane(LBM) and LNG into LNG fill-up and trial operation of an LNG truck in the Nihon Keizai Shimbun electronic version on Nov.18, 2022.

-

Achieved a total of 100 LNG fill-ups at the Ishikari filling facility

-

Achieved a total of 100 LNG fill-ups at the Tomakomai filling facility

-

Commenced trial operations of the Ishikari filling facility

Purpose of the Project

The project aims to contribute to the reduction of CO2 emissions in the transportation sector. It addresses the challenges of electric vehicles (“EVs”) and hydrogen fuel cell vehicles (“FCVs”) for heavy-duty trucks, such as limitation in driving range and payload capacity, as well as its lengthy charging/refueling times. LNG-powered trucks ("LNG trucks") are practical and immediate solution towards achieving a carbon-neutral society.

LNG trucks are capable of continuous long-distance travel exceeding 1,000km, a range currently challenging for EVs and FCVs. Further, LNG trucks are expected to reduce CO2 emissions by approximately 10% or more compared to conventional diesel trucks.

In collaboration with Air Water Inc. ("Air Water"), from 2021 to 2024, Mitsubishi Corporation had conducted demonstration trials using Japan’s first compact LNG filling facility and LNG trucks. After completing the demonstration period, we have continued the operation of this project to promote the adoption of the use of these systems throughout Japan.

Overview of the Project

Selected for the Ministry of the Environment's Demonstration Project

In May 2021, the project was selected for the Ministry of the Environment's "Low Carbon Technology Research and Development Program"*1.

In Feb 2024, a compressed natural gas (CNG) filling system*2 was added to the LNG filling facility, and commenced CNG filling to LNG trucks.

Ministry of the Environment's demonstration trial period concluded at the end of March 2025, and we continue the LNG filling project for LNG trucks with the support of various project partners.

Additionally, this project supports "Zero Carbon Hokkaido"*3, promoted by the Hokkaido Government.

*1 From FY2022, the program was renamed to "Demonstration Project for Accelerating Practical Use of Innovative CO2 Emission Reduction Infection Control Technologies."

*2 CNG refers to Compressed Natural Gas, which is natural gas in a compressed state (unlike LNG, which is in a liquid form). Current LNG trucks are designed to utilize CNG as an auxiliary fuel during engine warm-up and under heavy load, requiring regular CNG refueling.

*3 "Zero Carbon Hokkaido" is an initiative led by the Hokkaido Government aiming to achieve Hokkaido’s net-zero greenhouse gas emissions by 2050. The initiative seeks to advance decarbonization, economic revitalization, and sustainable community development through the cooperation of residents, businesses, municipalities, and organizations.

Achievements in Facility and Vehicle Operations

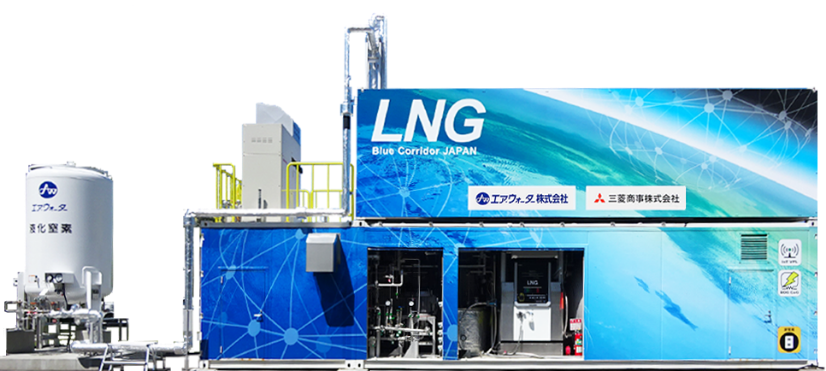

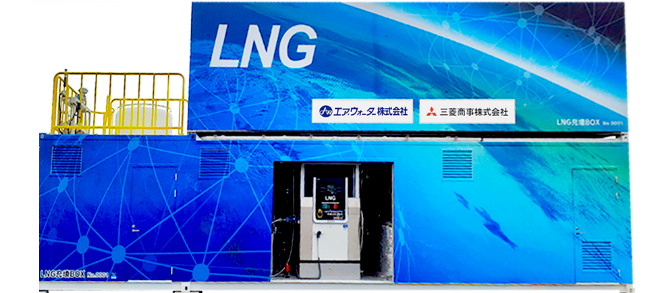

In April 2022, the LNG filling facility commenced operations in Tomakomai City, Hokkaido, followed by the start of operations in Ishikari City in June 2022. Fourteen LNG trucks (Isuzu-made, LNG GIGA) began demonstration runs around these facilities.

Since the start of the demonstration runs in April 2022, the cumulative mileage of LNG trucks has exceeded 2.3 million kilometers as of March 2025, with no significant issues. Both the LNG filling facility and LNG trucks have maintained stable operations, comparable to conventional diesel vehicles, including necessary refueling time.

In July 2024, two LNG-fueled tractor heads manufactured by Volvo were introduced into the demonstration runs, with their operations commencing in August of the same year.

Introduction of Liquefied Biomethane

In November 2022, the Tomakomai LNG filling facility initiated the mixing of liquefied biomethane(LBM) with LNG, and the refueling/demonstration runs of LNG trucks using this LNG/LBM mixed fuel began.

The LBM is produced from biogas derived from livestock manure in Hokkaido. To date, LBM mixing has been conducted seven times at the Tomakomai LNG filling facility, with the LBM proportion in the LNG/LBM mixture reaching a maximum of approximately 65%.

-

-

LNG tractor head manufactured by Volvo Trucks

LNG tractor head manufactured by Volvo Trucks -

- Liquefied Nitrogen Tank

- Cogeneration Dynamo

- Boil Off Gas Reliquefaction Facility

- LNG Storage Tank

- Hot Water Boiler

- Temperature RegulatorHot Water Evaporator

- LNG Dispenser

- Boil Off Gas Buffer Tank

- UPS Facility

Ishikari LNG filling facility -

Tomakomai LNG filling facility

Tomakomai LNG filling facility- Liquefied Nitrogen Tank

- Boil Off Gas Reliquefaction Facility

- LNG Storage Tank

- Boil Off Gas Buffer Tank

- LNG Dispenser

- Temperature RegulatorHot Water Evaporator

- Hot Water Boiler

Project Partners

Project Partner

Project Participants

- Hokkaido Electric Power Company, Inc.

- Isuzu Motors Ltd.

- Air Water Specialized Transportation Inc.

- Hokkaido Trucking Association

- UD Trucks Corporation

(Volvo Trucks)

Project Participants for Operations of LNG Trucks

Relevant Government Agency

FAQ

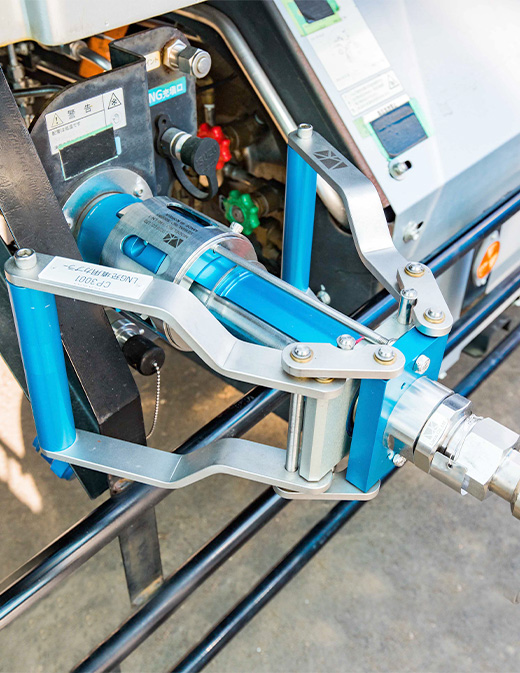

What are the characteristics of the LNG filling facility?

Under the assumption that the LNG filling facility will be set up in the logistics centers of carriers, the partners downsized it so that it can be set up in the parking space of one heavy truck. It is capable of fueling 50 to 60 heavy LNG trucks per day with a fueling time of just 10 minutes per truck. The amount of LNG remaining in the LNG filling facility can be viewed remotely, and by creating a system in which LNG replenishment occurs at the appropriate time with the appropriate amount for the LNG filling facility, the partners plan to establish a stable LNG supply system for the LNG filling facility.

Additionally, CNG filling equipment has been added to the LNG filling facility at the Tomakomai filling station, enabling to fill both CNG(which is used as supplementary fuel for LNG trucks) and LNG.

What is the advantage of using LNG as automobile fuel?

Unlike trucks powered by electric batteries or fuel cells, LNG trucks have ranges in excess of 1,000 kilometers and sufficient load capacity.

They are expected to be capable of reducing CO2 emissions by more than 10%* when compared to diesel trucks. LNG trucks have reduced vibration and noise, and special characteristics include their exhaust being extremely green and their lack of a petroleum smell similar to diesel.

* LNG trucks built by Isuzu Motors Ltd. was used in tests undertaken as part of the Ministry of the Environment's “Low Carbon Research and Development Program," which ran from 2016 to fiscal year 2018. The tests confirmed that the truck had a range of more than 1,000 (primarily highway) kilometers per fill-up in city-to-city transport, and that it also produced less than 90% of the CO2 emissions produced by diesel trucks that meet Japan's heavy vehicle fuel efficiency standards set in fiscal year 2015.

What are the details of the trials?

From 2021 to 2024, Mitsubishi Corporation and Air Water has performed trials using 14 LNG trucks manufactured by Isuzu Motors Ltd. and LNG trailer head manufactured by Volvo Trucks Corp. for the commercialization of the LNG filling facility. With the cooperation of Hokkaido Electric Power Co., Inc., the partners plan to assess the system's overall feasibility towards social implementation and how much it can reduce CO2 emissions and fuels costs typically generated by LNG trucks. The results of the tests will help the partners to determine whether or not to make the system commercially available. We also conducted mixing the LNG with liquefied biomethane to further reduce CO2 emissions.

How is the safety of the LNG filling facility?

LNG, which fuels LNG trucks, uses a dedicated nozzle and is completely sealed off as it is an extremely cold liquid. In order to avoid the risk of cold burns, etc. due to touching things that have cold areas, LNG fueling workers must wear protective gloves and face guards. In addition, there are safety measures such as the prohibition of handling heat around the Facilities.

Furthermore, the LNG tank in the LNG filling facility is a dual structure, and the risk of an LNG leak is as low as it could possibly be. In the unlikely event that LNG leaks onto the ground, it will vaporize and dissipate as vaporized gas is lighter than air, and it will not contaminate the land or water as LNG is not poisonous.

For inquiries:

Environmental Energy Group CEO Office

Isuzu Business Division, Mobility Group