Promoting Stable, Sustainable Societies and Lifestyles

Promoting Stable, Sustainable Societies and Lifestyles

MC promotes sustainable societies and future lifestyles through businesses across various countries and industries, while fulfilling its responsibility to provide a stable supply of resources, raw materials, products, services, and other offerings in line with customer needs.

Related SDG Themes

Action Plan for This Material Issue

Ensuring the stability of people’s lives is one of MC’s core mandates, and the company believes it is essential to achieve this in a sustainable manner through its business activities. While continuing to provide the goods and services necessary to maintain current societal systems, MC will advance businesses that drive society toward a more sustainable future.

Fulfilling MC’s Responsibility for Ensuring a Stable Energy Supply to During the Transition Period

Global energy demand is expected to rise due to population growth and economic development. While the shift to renewable energy in the power sector will continue, significant technological innovation is required to address challenges such as intermittency and location constraints. To meet growing energy needs and achieve a carbon-neutral society, decarbonizing fossil fuels remains essential.

MC is committed to ensuring a stable supply of natural gas and LNG, which have relatively low environmental impact among fossil fuels. At the same time, MC will work to reduce GHG emissions across the value chain through operational efficiency improvements, CCUS, and other methods.

Tangguh LNG Project Initiatives

The Tangguh LNG Project, located in Papua Barat Province, Indonesia, is the country’s largest gas-producing project, accounting for approximately 30% of domestic gas output. MC participates in the project as a joint venture partner with BP, the project operator. Since beginning operations in 2009, Tangguh has safely delivered more than 1,900 LNG cargoes to global markets, including Indonesia and Japan. In 2023, the addition of a third LNG train increased production capacity by 3.8 million tons per year, bringing total capacity to 11.4 million tons annually.

Furthermore, in 2024, a final investment decision was made for an upstream development plan that includes Indonesia’s largest CCUS (Carbon Capture, Utilization, and Storage) project, which is expected to advance CCUS technology in the country. In response to declining production in existing blocks, MC is also actively pursuing new upstream developments around the Tangguh area.

Major Progress

Ensuring a Stable Supply of High-quality Steelmaking Coal

Steel is a basic material that is difficult to replace, and its demand is expected to remain strong over the long term in line with global economic growth. In the steel industry, the ironmaking process (blast furnace method), which primarily uses iron ore, generates significant GHG emissions. While the use of electric furnaces that rely on steel scrap and the adoption of hydrogen in ironmaking are expected to expand in the future, these technologies will require considerable time to mature and for production facilities to transition. Therefore, decarbonizing the blast furnace process, which remains the mainstream process, is a critical near-term challenge. MC will continue to contribute to the decarbonization of the steel industry by ensuring a stable supply of high-quality steelmaking coal—one of MC’s major commodities and a key raw material for the blast furnace process—while supporting efforts to reduce emissions in existing production methods.

MDP Initiatives

Mitsubishi Development Pty Ltd. (MDP), which engages in the exploration, development, production, and sales of mineral resources, jointly operates its steelmaking coal business, BMA, in partnership with BHP. BMA is one of the world’s largest steelmaking coal operations and fulfills its responsibility to provide a stable supply of high-quality steelmaking coal that supports the decarbonization of the blast furnace steelmaking process. In April 2024, MDP completed the divestment of certain coal mines, consolidating its holdings in high-grade coal assets.

Looking ahead, MDP will continue efforts to reduce GHG emissions from BMA’s production processes while remaining responsive to changes in the business environment. In collaboration with BHP, MDP is also supporting research aimed at reducing emissions across the entire steelmaking coal value chain. For example, MDP entered into a partnership with ArcelorMittal, Mitsubishi Heavy Industries, Ltd., and BHP to apply CO2 capture technology in steelmaking and jointly conduct demonstration tests at ArcelorMittal's steel works.

Sustainable Food Supply

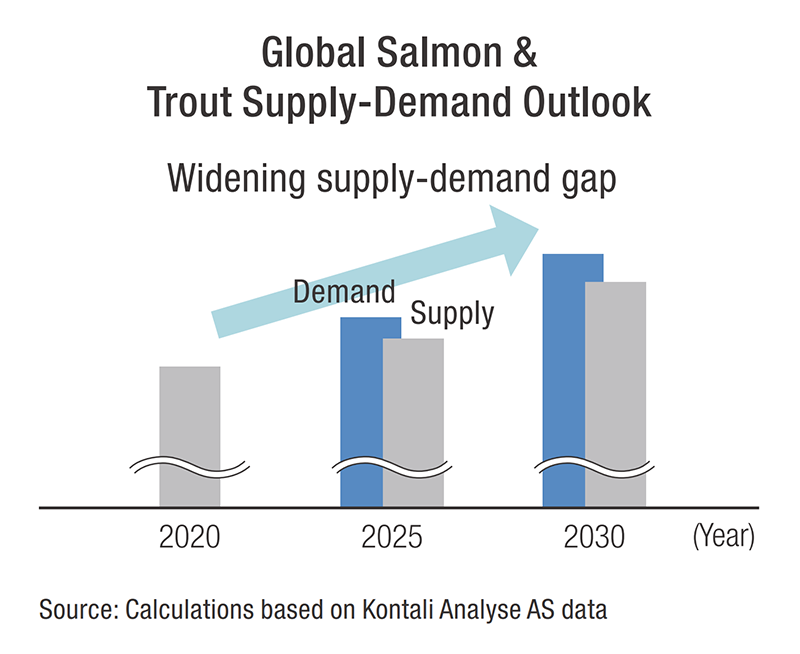

As global population growth drives rising food demand and interest in sustainability continues to increase, establishing a sustainable production and supply system has become increasingly important. MC is committed to developing a business model that integrates sustainable production, processing, and sales. The company is expanding its range of products certified by international fishing and farming standards such as the Marine Stewardship Council (MSC) and the Aquaculture Stewardship Council (ASC), while also promoting transactions with suppliers that adhere to its Policy for Sustainable Supply Chain Management.

Cermaq Initiatives

Cermaq, one of the world’s leading companies in salmon (including coho) farming, processing, and sales, became a subsidiary of MC in 2014. Operating in Norway, Chile, and Canada, Cermaq produces approximately 200,000 metric tons of salmon annually, delivering sustainable, high-quality farmed salmon to consumers worldwide.

Biodiversity protection is a core element of Cermaq’s license to operate across all regions. The company actively collaborates with local stakeholders to safeguard biodiversity, including salmonid species in its farming areas. Cermaq monitors benthic impacts, tracks bird and marine mammal mortalities at its sites, and ensures compliance with the laws and regulations of Chile, Canada, and Norway, as well as additional requirements under certification standards such as ASC and BAP. Furthermore, Cermaq participates in beach-cleaning initiatives in its operating regions, regardless of the source of the litter.

Cermaq’s Feed Supplier Code of Conduct mandates that no fish meal or fish oil used in its feed originates from IUU (Illegal, Unreported, and Unregulated) fisheries and that all soy used is deforestation-free.