Efficient Use of Resources : Initiatives

Initiatives

Recycling and Closed-Loop Business Initiatives (Livestock Feed Production Business)

Nosan Corporation, a consolidated subsidiary of MC, uses Eco Feed* as a raw material for its formulated livestock feed, with the aim of helping to increase the food recycling rate and enhance the livestock feed and food self-sufficiency rate. Currently, Nosan Corporation uses approximately 7,000Mt per year of dried Eco Feed recycled from discarded by-products of food production, unsold food products, leftovers from cooking etc., as well as approximately 20,000Mt per year of by-products from bakeries and confectionery factories (breadcrumbs, cake flour). These are used as raw materials for livestock feed.

-

*A livestock feed manufactured using by-products of food production (by-products obtained from the food production process), unsold food products (bread and boxed lunches, etc.) leftovers from cooking (cut vegetable scraps and other leftovers from cooking) and residual farm products (imperfect farm produce, etc.).

Recycling and Closed-Loop Business Initiatives (Livestock Business)

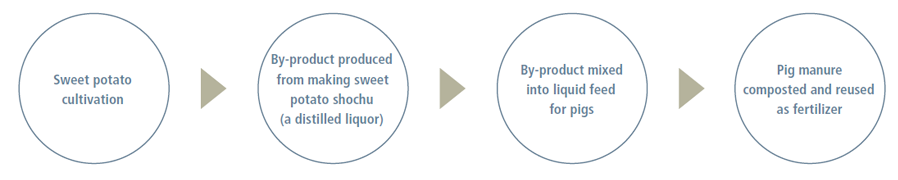

Japan Farm Holdings Inc., a consolidated subsidiary of MC, is a large-scale livestock company that is working to build a closed-loop recycling model. The model is centered on reusing waste generated from a primary industry, specifically the lees left over from producing the distilled liquor shochu. Japan Farm Holdings is located in Kagoshima Prefecture, which is famous for sweet potato shochu manufacturing. The by-product waste known as lees from shochu manufacturing had been an ongoing issue. To solve this problem, Japan Farm worked in collaboration with local distilleries for over two years to develop feed that reuses the shochu lees. The feed is used for breeding pigs for “Brand Pork.” In addition to reducing waste disposal costs and CO2 emissions, this model also involves the manufacture of fertilizer from manure produced by the pigs that consume the feed. This fertilizer is then sold by local vendors, such as agricultural cooperatives, for use in farming.

Japan Farm also maintains and operates a biomass power generation facility that uses chicken manure from the farm as fuel to generate "steam and electrical energy" for effective use. The electricity generated is used as a power source for the facility, while the steam generated by the boiler is used as a heat source. Ash generated during the incineration process is sold to outside parties as a raw material for fertilizers that contains effective minerals.

Participation in the PET*1 Chemical Recycling Business

In January 2020, MC entered the PET chemical recycling business (MC’s equity share: 34%) through an investment in Thai Shinkong Industry Corporation Ltd., which produces PET resins for beverage bottles.

PET is highly recyclable mono-material with a wide range of applications, including in food and beverage containers as well as in textiles, thanks to its excellent transparency, barrier properties, and well-established collection and recycling systems. As the transition to a circular economy progresses worldwide, we will expand our capacity for producing PET resins, for which demand is expected to grow in line with the shift towards mono-materials, and by introduce chemical recycling technologies*2 through our participation in the PET chemical recycling business with the aim of “Conserving and Effectively Utilizing Natural Capital”.

While environmental awareness in relation to plastics is heightening worldwide, plastics are highly functional basic materials that underpin sustainable economic development. In promoting its plastics business, MC aims to contribute to building a circular society by improving recycling rates and developing alternative materials.

-

*1An abbreviation of polyethylene terephthalate.

-

*2A recycling method in which used plastics are chemically decomposed into the raw material (molecular level) and then re-polymerized. This allows reuse of resources without any degradation in quality due to recycling.