Climate Change : Structure

Governance

MC recognizes climate change as one of its key management issues. Since initiating discussions on the resilience of our business to climate change in 2016, we have established and are expanding internal mechanisms to integrate climate change and other ESG factors into the decision-making process for business strategy and operations across the MC Group.

Figure 1 Main initiatives to date

Our Climate Governance Structure

MC’s approach to, and policies on, climate change are formulated and regularly reviewed by its Executive Committee, MC’s officer-level decision-making body. Furthermore, as stipulated in the regulations governing MC\'s board of directors, the Executive Committee reports its findings regularly (approximately three times a year) to the Board of Directors.

Board of Directors and Executive Committee Deliberations and Reports

| Basic Policy on Climate Chang | Covers climate-related initiatives through MC’s businesses, adoption of the TCFD recommendations, details on climate-related financial disclosures, etc. |

|---|---|

| Important Matters | Assessments of climate-change risks and business opportunities (including scenario analyses), GHG reduction targets and status of reduction initiatives, etc. |

Brief review of Our Climate Governance Process

Prior to deliberation by the Executive Committee on the basic policy and other important matters, we incorporate advice and recommendations from external experts through the Sustainability Roundtable. Based on these insights, the Sustainability Committee (a subcommittee of the Executive Committee), which consists of all Business Group CEOs. Additionally, Group Chief Sustainability Officers and Group Sustainability Managers are appointed within each Group. These individuals are responsible for developing a salient management strategy, overseeing sustainability-related initiatives including climate action, and strengthening climate-related initiatives and insight for their respective businesses and strategies. The above Basic Policy and Important Matters are therefore comprehensively addressed when making key decisions on business strategy, as well as when screening new investment and loan proposals.

Climate-Change Governance Structure

| Board of Directors | Supervises MC’s climate-related actions and initiatives | Convenes approx. three times a year |

|---|---|---|

| Executive Committee | Makes decisions regarding MC’s basic policy on climate change Makes decisions regarding important matters pertaining to climate change | Convenes approx. twice a year |

| Sustainability Committee (reports directly to Executive Committee) | Deliberates on MC’s basic policy on climate change and important matters therein, and reports findings to Executive Committee | Convenes approx. once a year |

| Sustainability Roundtable | Offers advice and recommendations regarding MC’s basic policy on climate change and important matters therein | Convenes approx. twice a year |

| Officer in Charge | Kenji Kobayashi (Executive Vice President, Corporate Functional Officer, CSEO) | |

| Department in Charge | Sustainability Department | |

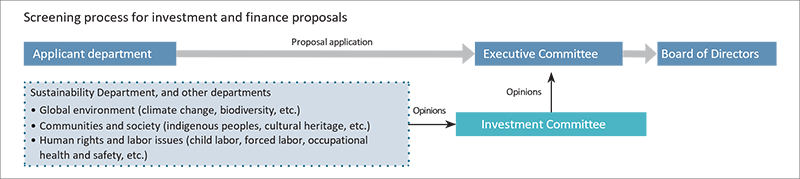

Screening Process for Investments and Loans

MC ensures that all loan and investment proposals submitted for review by the Board of Directors and the Executive Committee are first deliberated by the Investment Committee, a subcommittee of the Executive Committee.By including the General Manager of the Sustainability Department in Investment Committee meetings (as a committee member), MC guarantees that the screening and decision-making process comprehensively considers environmental and social impacts. Besides screening new proposals, the Investment Committee also strives to implement improvements for existing business investees, by monitoring their management practices for continued improvements and value enhancement. From the perspective of climate change-related transition risks/opportunities and physical risks, the review of proposals and decision-making processes considers quantitative data such as GHG emissions, as well as national policies and industry trends. Since August 2022, when screening new investment proposals for “Transform” and “Green” businesses, which we identify as having significant climate change transition risks and opportunities, in accordance with the “MC Climate Taxonomy” we have been conducting profitability assessments based on indicators (such as internal carbon pricing) that use key assumptions under decarbonization scenarios.

Introducing Mechanisms for Simultaneously Decarbonizing and Reinforcing our Portfolio

In order to achieve the GHG reduction targets (halve by FY2030 (FY2020 baseline), net zero by 2050) outlined in “The Roadmap to a Carbon Neutral Society”, as sustainability policies to address climate change, we have mechanisms for simultaneously decarbonizing and reinforcing our portfolio as shown in figure 2.

Figure 2: Mechanism for simultaneously decarbonizing and reinforcing our portfolio.

The basis for this mechanism is our “MC Climate Taxonomy”, a new business classification system implemented in FY2022. MC Climate Taxonomy, which covers all of our business units, classifies each into 3 categories: Green (businesses with significant climate-related transition opportunities), Transform (businesses with significant climate-related transition risks), White (Other). For businesses classified as Green or Transform, appropriate governance and risk management systems have been adopted to carry out evaluations using assumptions under decarbonization scenarios when screening individual investment proposals, confirm GHG reduction plans when formulating investment plans, and confirm that our business is aligned with a 2050 net zero scenario in terms of both individual projects and company-wide business strategy.

The concrete classification process is shown in Figure 3. In selecting “Transform” businesses, both the volume of GHG emissions (Scopes 1, 2 and 3) and the barriers that exist in reducing GHG emissions are considered. In order to determine the specific reduction barriers, we use indicators such as Scope 1 6.5 Gases (emissions that are unavoidable in the course of business) and Scope 3 Category 11 (GHG emissions associated with the use of products sold), from the perspective of avoiding stranded assets.

Figure 3: MC Climate Taxonomy Approach

- *1Businesses where demand in 2050 under the 2.0℃ scenario will increase by 20% or more compared to the current business

- *2We first identified industries with high GHG emissions based on the EU Taxonomy. All other businesses are also classified into this category if they have exceptionally high emissions compared to other industries, based on internal Scope1 data and external Scope 3 Category 11 data.

- *3Determined based on GHG emissions, including Scope 1 and Scope 3 Category 11.

The mechanism for simultaneously decarbonizing and reinforcing of our portfolio, including the MC Climate Taxonomy, is effectively managed via the 5 steps outlined in Figure 4.

Figure 4: Mechanism of initiatives

1.5℃ Scenario Analysis

Approach to Scenario Analysis

Climate scenarios explore different potential states of the world in which different temperature trajectories are achieved based on a series of consistent outcomes and assumptions relating to socioeconomic developments, policies, markets, and technologies. Scenarios are created and published by independent agencies, such as the International Energy Agency (IEA), the Intergovernmental Panel on Climate Change (IPCC), and the Network for Greening Financial Services (NGFS) - along with companies that seek to verify and evaluate potential climate risks and opportunities for their own businesses via the creation of their own scenarios.

In order to both decarbonize and reinforce our portfolio, we believe it is essential to conduct scenario analyses by referring to these climate scenarios, thereby allowing us to properly understand the transition risks and opportunities for each of our businesses and to take these into account in formulating business strategies. To this end, since FY2019, we have been conducting scenario analyses in line with the TCFD recommendations, using primarily IEA climate scenarios, and since FY2021, we began conducting scenario analyses using a 1.5°C scenario predicated on net zero by 2050.

The 1.5℃ Scenario Used in FY2022

We used the IEA Net Zero Emissions by 2050 Scenario (IEA NZE) as a reference for our 1.5°C scenario analysis in FY2021. However, the IEA NZE data lacks the granularity required to extract precise insights that reflect MC’s particular business characteristics and strategies. As such, MC collaborated with a third-party organisation to create and utilise a customised, specific model of the 1.5°C scenario (FY 2022 1.5°C Scenario), while aligning key assumptions with the IEA NZE wherever possible, thus allowing for a detailed level of granularity on topics like demand by region and product. Key assumptions for the FY2022 1.5°C scenario and the comparison with the IEA NZE are shown in Table 1 below.

Table 1 Key assumptions for the FY2022 1.5°C scenario and the comparison with the IEA NZE

Our FY2022 1.5°C scenario assumes both decarbonisation and economic growth similar to the IEA NZE, with an expected average annual growth rate of approximately 3% in GDP by 2050, and an expected population of about 9.7 billion in 2050.(See Table 1, ① and ②)

Global CO2 emissions are anticipated to decline by approximately 35% in 2030 compared to 2020 in this scenario, with the expectation that we reach net zero emissions in 2050, largely resulting from changes in land use (e.g., afforestation) and the implementation of negative emission technologies. The IEA NZE, published in May 2021, utilised 2019 as a reference year and projected a linear decrease in emissions toward 2050. Our FY2022 1.5°C scenario, however, reflects GHG emissions data through FY2021. As a result, GHG emission from 2019 to 2021 are marginally less than IEA NZE, though still in the acceptable range of reduction required to realise a temperature increase of less than 1.5°C, as presented by IPCC. (See Table 1 ③, Chart 1)

Chart 1 1.5°C-consistent pathways and GHG emissions presented by IPCC

- *1IEA NZE was created using 2019 as a reference year, and data only exists ata 10-year intervals from 2020. This model was calculated at one year intervals using the latest data, resulting in diferences in the current figures the accmulated impact of is greater.

- *2Values published in IEA NZE exclude GHG emission reductions resulting from changes in use of land (e.g., afforestation). There is also a proviso that about 1.3 Gt of GHG is expected to be absorbed annually as a result of land use in 2050.

- *3Data of Global Carbon Project include GHG emission reductions resluting from changes in use of land.

Under our FY2022 1.5°C scenario, final energy use in 2050 will be approx. 400 EJ. Furthermore, the electricity share in final energy use will reach approx. 50% in 2050 due to enhanced electrification from decarbonization efforts, leading to an expected global electricity demand of approx. 90 billion GWh/year (3 times or more compared to 2020 levels) (see Tables 1 ④ & ⑤). Regarding Table 1 ④ "Final Energy Use", which is considered to differ significantly compared to the IEA NZE, the IEA NZE assumes an average annual improvement in energy efficiency of about 4% and 2.7% from 2020 to 2030 and from 2030 to 2050, respectively, with 2019 as the base year. However, considering that energy efficiency improvements over the past decade have averaged less than 2% per year, the 1.5°C scenario used in FY2022 assumes a more conservative figure of approx. 2% improvement in energy efficiency per year on average through 2050. With regard to "Primary Energy from Oil and Gas", primary energy supply is expected to reach approx. 100 EJ in 2050, which is almost equal to the IEA NZE (Table 1 ⑥). We compared items ④ through ⑥ in Table 1 with the 1.5°C scenarios integrated and published by the WBCSD and confirmed that all of the figures fall within the range of these scenarios (Chart 2)

Chart 2 1.5°c scenarios integrated and published by the wbcsd

Influences and Considerations for the FY2022 1.5°C Scenario

While a series of validations through scenario analysis is widely recognized as beneficial as described above, the following points in particular should be noted.

- Scenarios are not future projections and include many inherent risks and uncertain factors and pathways. Accordingly, due to changes in such factors and other variables, the actual future world and GHG emissions reduction pathways may differ significantly from those indicated by scenarios.

- In the FY2022 1.5°C scenario, the energy mix is calculated based on future cost projections for each technology available at the time. Therefore, it should be noted that 1) the projections for currently less mature technologies are relatively less reliable. Additionally, the potential impact of policies on the cost competitiveness and adoption rate of each technology in each region has not been taken into account. Finally, the impact of resource price fluctuations on technology competitiveness has not been accounted for.

Results of the 1.5°C Scenario Analysis and Relevant Implications

Identification of Businesses Subject to Analysis

As a global integrated business enterprise with a global network of approx. 1,700 group companies, it is not feasible for MC to apply the scenario analysis to all of our businesses. As such, we selected businesses that are expected to be particularly affected by the risks and opportunities posed by climate change for our scenario analysis, according to the following process.

In selecting businesses from a risk perspective, we considered two indicators: GHG emissions and asset size.

First, we selected businesses that we categorised as "Transform" businesses under the “MC Climate Taxonomy” due to their high emission volumes and relative difficulty in reducing emissions. From among those businesses, we then selected those with significant asset sizes, namely natural gas/LNG, metallurgical coal, and power generation (fossil fuels) (these three businesses account for approx. 70% of the balance of investment out of all "Transform" businesses) as targets of the scenario analysis from a risk perspective. Since MC has already adopted a policy to not enter into any new coal-fired power generation businesses and achieve a 100% non-fossil power generation portfolio by 2050, power generation (fossil fuels) businesses were exempted, and thus natural gas/LNG and metallurgical coal were chosen as final target businesses for the FY2022 1.5°C scenario analysis.

From an opportunity perspective, among the "Green" businesses classified under the "MC Climate Taxonomy" as having significant opportunities related to climate change, we selected renewable energy, which is one of our core businesses and for which we have multiple existing projects, as the target business of the FY2022 1.5°C scenario analysis.

In the following sections, we explain the results of our analysis of the business environment in terms of risks and opportunities for the target businesses based on our 1.5°C scenario analysis, as well as our policy and other initiatives in light of these results.

Climate Risks

A. Natural Gas/LNG

The natural gas and LNG are important business areas for achieving a carbon neutral society and sustainable economic development, since natural gas and LNG play a variety of roles in the transition to a carbon-neutral society. Roles include being a complement to renewable energy intermittency, an energy source for sectors that are difficult to electrify, and being a raw material for next-generation energy sources. Given the importance of natural gas and LNG, MC conducted a detailed analysis based on the FY2022 1.5°C scenario. The following shows the results of MC’s analysis of the impact on our natural gas and LNG businesses under the FY2022 1.5 °C scenario, as well as our business strategy and initiatives.

【Analysis of Business Environment】

In formulating MC’s LNG business strategy, it is important to understand the trajectory and scale of LNG demand under the 1.5°C scenario, which assumes that decarbonization progresses. From this viewpoint, MC verified and analyzed (1) The primary energy supply of oil and natural gas, (2) Natural gas demand, and (3) LNG demand based on the FY2022 1.5°C scenario.

- (1)The Primary Energy Supply of Oil and Natural Gas

The ratio of oil and natural gas among primary energy supply does not differ significantly between the FY2022 1.5°C scenario and the IEA NZE. Both scenarios project that energy from oil and natural gas will decline to approximately 265-285 exajoules (EJ) in 2030, and to approximately 100 EJ in 2050. This figure falls within the range of other 1.5°C scenarios for 2050, including the IEA NZE published by the WBCSD (see Chart 3)

Chart 3 Primary Energy from Oil & Gas

- (2)Natural Gas Demand

There is no significant difference in global demand for natural gas between the FY 2022 1.5°C scenario and the IEA NZE from now to 2050. In each scenario, global demand until 2030 is expected to remain relatively stable, after which it is expected to significantly decline when renewable energy, hydrogen and other next-generation energy become widespread (see Chart 4).

Chart 4 Global demand for natural gas and LNG

- (3)LNG Demand

Demand for LNG is expected to increase following the rising demand for primary energy due to economic growth and the shift from oil and coal to natural gas in Asian countries. For those countries, this is especially the case where natural gas procurements through pipelines is impossible or domesctic production declines due to depleting natural gas reserves. Global LNG demand is even expected to increase until 2030 under the FY2022 1.5°C scenario. If decarbonization progresses beyond the commitments made by nations, demand for LNG, as well as natural gas, is expected to fall after 2030. However, the rate of decline in LNG demand is expected to be slower than natural gas, particularly in Asian countries for reasons mentioned above. Between the years 2040 and 2050, Asian countries are expected to account for over 90% of global LNG demand. IEA NZE only publishes data representing volumes traded between regions and not intra-regional trade, thus a calculation of LNG demand by region and a side-by-side comparison is not possible. However, it is reasonable to assume that the trend in Asia’s rising share of global LNG demand is consistent with IEA NZE data.

【Monitoring and Discussion Items for Transform Discussion】

In consideration of the business environment mentioned above, for natural gas and LNG businesses, MC will monitor and discuss at the management level the current status and trends of climate change transition risks and, more specifically, items that could affect supply and demand (see below) in the “Transform Discussion” introduced in the Midterm Corporate Strategy 2024 as one of the sustainability measures. Such results shall be incorporated into the final business strategy.

- Geopolitical risks such as the current energy crisis and situation in Ukraine

- Natural gas, LNG, and decarbonization policies of our partners, such as LNG consumers and major oil and gas companies

- Advances in low-carbon and decarbonizing technologies such as renewable energy, nuclear power, next-generation energy and CCUS(Carbon Capture, Utilization and Storage)

- Trends in climate change-related regulations, including policies on natural gas and LNG, and GHG emissions reductions by various governments

【Policies and Initiatives Based on the Business Environment and Transform Discussion】

Natural gas and LNG are energy sources that will play a key role in the transition period. Under the FY2022 1.5°C scenario used in this analysis, although natural gas and LNG demand is expected to decline overall in the long term, Asia, which is a strategic region for MC’s LNG business, is still expected to maintain a certain level of demand in the long-term.

Taking into account the business environment mentioned above, MC will be focusing on strengthening its LNG business and decarbonizing its LNG value chain in order to achieve a stable supply of energy and resources as well as decarbonizing its social and economic activities.

For the longer term, MC shall continue to: 1). work on initiatives to progress the decarbonization of its LNG value chain, 2). optimize its LNG portfolio, and 3). investment in next-generation energy, while closely monitoring the overarching business environment, including the development on technological innovation and climate-related regulations by various governments.

<Strengthening MC’s LNG Business>

The majority of the production volume from MC’s existing LNG business is sold under long-term contracts. However, MC will continue to improve the competitiveness of its existing LNG business by enhancing operational efficiency and cost reductions, while optimizing its portfolio. For new LNG businesses, MC will make investment decisions by also considering investment viability under various decarbonization scenarios, including the 1.5°C scenario, taking into account the risk of it becoming a stranded-asset in the event decarbonization occurs rapidly.

- Natural gas and LNG-related data

- Involvement in LNG Projects, Equity Share of Oil and Gas Upstream Production

<Decarbonization of MC\'s LNG Value Chain>

Together with strengthening its LNG business, MC intends to leverage its position and strength as one of the biggest LNG players in Japan to play a key role in transitioning to a decarbonized society, by the promotion of CCUS, and activities in the production and supply of next-generation energy such as blue hydrogen or e-methane (synthetic methane), which will all contribute to the decarbonization of the LNG value chain. MC believes that its experience, knowledge, and networks gained from the natural gas and LNG businesses over the past 50 years can be utilized in specific new business fields mentioned below.

B. Metallurgical Coal

Through Australian subsidiary Mitsubishi Development Pty Ltd., MC conducts exploration, development, production, and sale of mineral resources in collaboration with its partner BHP. The BHP Mitsubishi Alliance (BMA), which we operate as a joint venture with BHP, is one of the world’s largest metallurgical coal operations, with an annual production volume of over 60 million tons and a share of approximately 30% of the global seaborne metallurgical coal market. Steel is an essential industrial material that every country needs in order to achieve economic growth. MC expects to see continued strong demand for steel, as it is a key component of efforts to develop the infrastructure needed to achieve decarbonization. However, the steel industry has yet to implement large-scale, low-carbon steelmaking methods. In addition, it would take many years for any low-carbon steelmaking method that is developed to be adopted worldwide. MC therefore anticipates a transitional period lasting several decades, during which growth in the use of electric furnaces for steelmaking from scrap iron will be accompanied by a shift to hydrogen-based steel production in conjunction with the advent of a hydrogen-based society. In the meantime, blast furnace steelmaking using metallurgical coal is expected to remain the primary steelmaking method in the foreseeable future. Given these circumstances, MC has carried out the following analysis of the outlook for the business environment under the 1.5°C scenario, the transition risks for its metallurgical coal business, and the business policies and initiatives needed to adapt to these changes.

【Analysis of the Business Environment】

BMA’s main product is high-quality metallurgical coal, which BMA supplies to the global seaborne markets. As part of the analysis of the business environment surrounding BMA under the 1.5°C scenario, MC carried out step-by-step evaluations of (1) demand for steel, (2) crude steel production by iron source, and (3) pig iron production and the maritime trade in metallurgical coal.

- (1)Demand for Steel

Steel is an excellent basic material and supports economic growth in every country. It also plays a vital role in the development of infrastructure for achieving decarbonization. Under the FY2022 1.5°C scenario, demand for steel in 2050 is expected to exceed the 2020\'s level (see chart 5). Furthermore, since achieving net-zero emissions by 2050 will require rapid action to create infrastructure related to decarbonization, consumption for steel can be expected to expand rapidly from the second half of the 2020s. The IEA NZE predicts a similar level of growth in steel production. These forecasts suggest that demand for steel is likely to remain steady over the long term, even if major strides are made toward the realization of a decarbonized society.

Chart 5 Trends in global steel consumption under the 1.5°C scenario (2020=100%)

- (2)Crude Steel Production by Iron Source

The steel industry is seen as a sector in which the reduction of GHG emissions poses major challenges. Efforts are being made to reduce carbon emissions, such as by making further improvements to electric furnace technology and developing hydrogen-based steelmaking technologies. Particularly significant is the hydrogen-based direct reduced iron (DRI) method, which is now being trialed primarily in Europe. However, even under the FY2022 1.5°C scenario and the IEA NZE, the commercialization of this technology is unlikely to take place with large scale until the second half of 2030. This is due to the need to solve various challenges, such as the development of hydrogen supply infrastructure, as well as the level of hydrogen price and carbon prices. Because of these, DRI technology is likely to be adopted gradually in the steel sector, starting in regions where the required conditions are in place, such as Europe. The adoption of this new technology is expected to occur at different times in different regions.

The expansion of electric furnace steelmaking is also expected to lead to a gradual decline in blast furnace pig ironmaking from 2030 onwards.The IEA NZE predicts a decline in blast furnace steelmaking, as well as reductions in carbon emissions from the blast furnaces that continue to operate, thanks to efficiency improvements and the adoption of CCUS technology. According to the IEA NZE, hydrogen-based production methods will account for around 30% of steelmaking by 2050, which is roughly in line with the FY 2022 1.5°C scenario(see Chart 6).

Chart 6 Crude steel production by iron source under the FY2022 1.5°C scenario

The demand for high-quality metallurgical coal produced by BMA is expected to decline more slowly than that for low-quality metallurgical coal, due to the relatively low greenhouse gas emissions from the blast furnace steelmaking process. High-quality metallurgical coal is attractive since there is a growing need for low-carbon measures that can be applied during the transition period when the blast furnace steelmaking process continues to be the prevailing method.

- (3)Pig Iron Production and the Maritime Trade in Metallurgical Coal

The gradual decline in pig iron production via the blast furnace steelmaking process will be accompanied by changes in the countries that comprise pig iron output. Pig iron production in China, which currently accounts for around 60% of the global total, is expected to decline, while production in emerging economies such as India and Southeast Asia is expected to grow (see Chart 7).Unlike China, India and many Southeast Asian countries are dependent on imported metallurgical coal, and demand from these countries is expected to sustain the global seaborne trade volumes. Almost all of the metallurgical coal produced by BMA is exported to handle in the seaborne market.

Chart 7 Composition of pig iron production by country under the FY2022 1.5°C scenario

【Monitoring and Discussion Items for the Transform Discussion】

As with MC’s natural gas and LNG businesses, conditions and trends relating to the following key aspects of the metallurgical coal business and their impact on business strategies are monitored and discussed at the management level through the “Transform Discussion.” The results of these discussions are considered in MC’s business strategies.

- The development of scrap iron collection and supply networks in China and emerging economies, and trends in electric furnace steelmaking

- Technological innovations, such as hydrogen-based steelmaking techniques

- The applicability of CCUS to the blast furnace steelmaking process, as well as trends in the development of CCUS-related laws and systems, and social acceptance of CCUS technology

- Carbon pricing trends in BMA\'s major markets

- Trends in approvals and the availability of financing for coal mine\'s development

【Policies and Initiatives Based on the Business Environment and Transform Discussion】

The steel industry is expected to see a long transition period and the need for high-quality metallurgical coal, which is BMA’s main product, will likely increase relative to low-quality metallurgical coal since it contributes to the reduction of emissions in blast furnace steel making process. On the other hand, the supply of metallurgical coal is expected to decrease as a result of the increasing difficulty of new mine\'s development such as difficulty of obtaining necessary approvals, and therefore fewer investments in new coal mines. BMA will continue to ensure a stable supply of high-quality metallurgical coal.

MC is also actively working to reduce BMA’s GHG emissions by exploring and implementing initiatives in areas such as renewable energy procurement, methane gas processing, and alternatives to diesel fuel. For example, BMA plans to transition 100% of the electricity used at its coal mines to renewable energy by 2027.

MC has also signed a collaborative agreement with its partner BHP, a major steel manufacturer, and a prominent engineering firm regarding the trial use of CCUS technologies in steelmaking. This initiative is part of MC\'s efforts to reduce GHG emissions throughout the entire steelmaking value chain.

In the mineral resources business, MC will work to promote its EX strategy from the three perspectives of decarbonization, electrification, and the shift to circular economies. In addition to efforts to decarbonize the steelmaking value chain, MC will also strive to expand its involvement in areas that are essential for electrification, such as copper and raw materials for battery, as well as its recycling business.

Climate Opportunity

Renewable Energy

Renewable energy is one of the core businesses of MC’s EX strategy. Renewable energy has been selected as a business with major transition potential in terms of climate change and several projects have already been developed. The following analysis was conducted under the FY2022 1.5°C scenario.

【Analysis of the Business Environment】

Electrification in a wide range of industries is essential in order to achieve net-zero emissions by 2050. It is assumed that a large portion of that electricity needed will be provided through renewable energy, mainly solar and wind power. As shown in Chart 8, in the FY2022 1.5°C scenario, the increase in the scale of total electricity generation and the share of renewable energy in that total generation due to the progress of electrification is very significant. This trend is also consistent with the IEA NZE.

Also, in line with the expansion of renewable energy, power generation amount of which varies according to weather conditions and which has a strong aspect as a distributed power source, further business opportunities are expected to increase, such as the expansion of transmission capacity, utilization of storage batteries, and demand response, which will contribute to improving the flexibility of the power supply and demand system.

Chart 8 Global Power Supply, and % of Renewable Power Supply

【Policies and Initiatives Based on the Business Environment】

The introduction of renewable energy and the spread of battery storage, as well as the accompanying trend toward decentralization of the power supply system, will vary according to country and region depending on the status of policies, regulations, and technological innovations, and the timing of their manifestation may differ significantly.

MC “produces” (generates) renewable energy, “integrates” weather-dependent electricity (through a sophisticated balance of supply and demand), and “delivers” this integrated electricity and high added-value services. By strengthening each of these functions of the power value chain, MC aim to expand our renewable energy business in Japan, where offshore wind power is expected to grow, and in Europe, where Eneco’s platform stands, as well as in the Americas, Asia, and other regions.

MC is making progress toward achieving its target to double its renewable energy power generation capacity from 3.3 GW in FY2019 to 6.6 GW by FY2030.

Specific Initiatives and Case Studies Related to Renewable Energy

<Initiatives in Europe for the Promotion of Renewable Energy (Eneco)>

Eneco is operating power generation businesses, power and gas trading businesses, power and gas retail businesses, and district heating businesses focused in the Netherlands, Belgium, and Germany with a core focus on renewable energy. With a solid customer base that is the third largest in the Netherlands, Eneco has approximately 1,800 MW of renewable energy assetss, which include the ones under construction status. In December 2022, MC and Shell plc were successful in the tender for the Hollandse Kust West Site VI offshore wind farm (760 MW capacity), located approximately 50 km off the Northwest coast of the Netherlands. This will be Eneco’s fifth offshore wind project in the Netherlands and seventh in Europe, bringing total capacity of offshore wind in the Netherlands to 2,500 MW. Renewable energy net equity base capacity will expand from 3,430 MW to 3,670 MW.

<Promoting Renewable Energy in the U.S. through Nexamp’s Distributed Solar Power Generation Business>

Through Diamond Generating Corporation, a wholly owned subsidiary power business in the U.S. MC operates Nexamp, Inc., a distributed solar power generation company. Nexamp\'s community solar business sets up solar power generation systems in local communities, allowing customers that cannot install solar panels to use solar-generated electricity in their homes or offices.

<Promoting Offshore Wind Power Generation Projects in Japan>

The consortium represented by Mitsubishi Corporation Energy Solutions Ltd. (currently Mitsubishi Corporation Offshore Wind Power Ltd.) was appointed by the government on December 24, 2021 as an operator for an offshore wind power generation project in the following promotion zones under the Act on Promoting the Utilization of Sea Areas for the Development of Marine Renewable Energy Power Generation Facilities. The consortium is moving ahead with the development of a seabed-anchored offshore wind power generation business, the first of its kind in Japan, for general sea areas.

- Promotion-zone offshore wind power generation project off the coast of Noshiro City, Mitane Town, and Oga City, Akita Prefecture

- Promotion-zone offshore wind power generation project off the coast of Yurihonjo City (northern side and southern side), Akita Prefecture

- Promotion-zone offshore wind power generation project off the coast of Choshi City, Chiba Prefecture

<MC Signs Japan’s First Long-term Corporate PPA for Online Retail Giant Amazon>

MC has signed a long-term Corporate Power Purchase Agreement (Corporate PPA), through which it will supply electricity to data centers owned and operated by the Amazon subsidiary Amazon Web Services, Inc. (AWS). Facilitated by MC Retail Energy Co., Ltd., this Corporate PPA represents Amazon’s first use of renewable energy in Japan.Under the agreement’s terms, West Holdings Corporation will build and maintain roughly 450 solar power stations (with a total installed capacity of approximately 22 MW) for Amazon and supply the online retailer with wholesale electricity. MC subsidiaries Mitsubishi Corporation Energy Solutions Ltd. and ElectroRoute will also be involved. The former will manage construction of the solar power facilities and provide tech support, while the latter will forecast the facilities’ outputs and hedge power generation imbalances*.

- *Investments to hedge costs incurred through supply-demand imbalances that occur when solar power outputs fail to match their original forecasts

- Renewable energy related data

- List of Renewable Energy Businesses

Summary

As presented above, by aligning key assumptions with the IEA NZE to the extent possible and referring to our FY2022 1.5°C scenario, which includes more granular data such as demand by region and commodity, we were able to analyze the business environment surrounding natural gas/LNG and metallurgical coal, which have considerable GHG emissions and are particularly large assets, from a risk perspective. From an opportunity perspective, we analyzed the business environment surrounding renewable energy, where we believe business opportunities will increase as society continues to decarbonize

The results of our FY2022 scenario analysis above exemplify the resilience of MC’s business portfolio, even under a 1.5°C scenario assuming rapid society-wide decarbonization.

Physical Risks

MC is working to realize a decarbonized society through its businesses across the globe. Nevertheless, we are aware that our businesses are also exposed to physical risks associated with climate change. In addition to the transition risks and opportunities assessed in the aforementioned 1.5°C scenario analysis, we have also analyzed the potential impact of physical risks (e.g., flooding, drought, rising temperatures, etc.) on MC Group businesses.

Main Physical Risks:

| Increase in Unusual Weather Patterns | Risks of water shortages, floods and other resulting phenomena having an adverse impact on business operations |

|---|---|

| Climate Change | Risk of rising temperatures, etc. having an adverse impact on businesses |

Physical Risk Assesment Process

With a global portfolio of companies with a diverse range of assets, it was important first to determine which MC Group assets are most exposed to the physical impacts of climate change. As such, MC has employed the following assessment process, starting with the identification of key assets.

Phase 0: Identification of Material ssets

To determine MC Group assets that are material to the operational performance of MC, MC first identified a subset of subsidiaries/ affiliates that have the greatest potential to have a material financial impact on MC using financial metrics such as profits and total asset values, and then identified assets that are material to their business.

Phase 1: Screening

MC engaged an independent specialist consultant to conduct a climate hazard screening exercise to identify high-risk assets that should undergo a detailed analysis. This assessment focused on 74 assets across 38 MC subsidiaries/affiliates located in 13 countries that were identified as material. During the screening process an evaluation of exposure to hazards through to 2030* was conducted, using observational data and climate model projections. The hazards included in this evaluation included coastal flooding (storm surges, sea level rise), stormwater flooding, wildfires, temperature rise, cyclones, and droughts. The evaluation employed the Intergovernmental Panel on Climate Change (IPCC)’s Representative Concentration Pathway (RCP) 8.5 scenario.

Each asset was assigned a numerical exposure score for each climate hazard. Each asset was then given a qualitative exposure rating (‘High’, ‘Medium’, or ‘Minimal’) based on the asset’s overall numerical hazard exposure score.

| Hazard Exposure Rating | Description |

|---|---|

| High | Overall hazard score greater than 30 |

| Medium | Overall hazard score 15-30 |

| Minimal | Overall hazard score less than 15 |

Phase 2: Detailed Analysis

On the basis of the screening results, 18 of the high ranked assets located in eight countries were selected for a more detailed climate hazard analysis in this phase. The purpose of the detailed analysis was to scope the current and anticipated physical climate hazards for each asset through to 2080 (evaluated over three time frames: 2030, 2050, and 2080) - using observational data, climate model projections, and information such as previously experienced impacts due to physical climate hazards. The analysis in this phase also employed the IPCC’s Representative Concentration Pathway (RCP) 8.5 scenario, along with the RCP 4.5 scenario in order to conduct a risk analysis for a moderate range of temperature increase.

The potential severity of climate hazards for each asset were ranked by considering the probability that the climate hazard will occur, the magnitude of the hazard’s impact on the asset, and the likelihood of the asset being affected. These were then ranked on 5-level color scales (red, orange, yellow, green and grey), indicating priority areas for adaptation strategies and activities.

| Hazard Rating | Description of Hazard Severity and Level of Recommended Action |

|---|---|

| 4 | Present-day hazards causing material impacts. Adaptation strategies should be evaluated and deployed. |

| 3 | Imminent hazards likely to result in material impacts during the planning time horizons. Adaptation strategies should be developed in the near future. |

| 2 | Lower likelihood or lower impact hazards which may occur during the asset hold period but are unlikely to cause material impacts and/ or for which more information is required. Impacts should be monitored but may not need action at this time. |

| 1 | Hazards currently modeled to have minimal impact and/ or to occur after the planning time horizons; may be re-evaluated in the future. |

| 0 | Site is not exposed to this hazard. |

Physical Risk Assessment Results

The results of the assessment are shared with each MC Group company to inform their future adaptation measures. The current measures and future adaptation strategies for assets that received a red hazard ranking for any of the hazard types covered by the assessment are detailed below.

Metallurgical Coal Business

| Assets subject to assessment | Mines and coal terminal owned by BHP Mitsubishi Alliance (BMA)* |

|---|---|

| Location | Australia |

| Type of hazard | Stormwater flooding |

| Current measures | Given that flooding due to heavy rain at mines has the potential to disrupt operations, the following measures have been implemented to improve resilience of the sites to flooding since the last flood events in 2011:

|

| Future adaptation strategies | MC together with BMA will continue to enhance physical risk mitigation in response to climate change forecasts. |

- *To address the risk of the storm surges associated with cyclones at the coal terminal, which was ranked as orange in the assessment, the latest port berth infrastructure installed has been designed to withstand a 1 in 1000 year wave event factoring in rises in sea levels and cyclone impacts due to climate change. An additional project is currently underway to upgrade an older berth to the same design standard.

Copper business

| Assets subject to assessment | Copper mines owned by Anglo American Sur, S.A |

|---|---|

| Location | Chile |

| Type of hazard | Drought |

| Current measures | While most of the water required for the operations is reused within the mine, a certain amount is lost due to evaporation and other factors, and this water must be replenished from external sources. Since in the drought condition, there is a possibility that sufficient water intake may not be possible which could affect operations, resilience measures are considered through increased procurement of industrial wastewater and treated sewage from third parties. |

| Future adaptation strategies | In addition to the current measures, further diversification of external water procurement is under consideration. Moreover, new initiatives to further improve water reuse efficiency at the operations are also being considered. |

Involvement in LNG Projects, Equity Share of Oil and Gas Upstream Production

MC’s equity share of oil and gas upstream production is as shown in the data below. GHG emissions from burning natural gas relatively lower compared to when burning other fossil fuels, and the demand for natural gas is forecasted to grow in line with the transition to a low-carbon and decarbonized society. Accordingly, MC has positioned natural gas as a core business. Currently, natural gas accounts for approximately 85% of MC’s equity share of oil and gas production.

Please refer to the ESG Data at link below for data on Involvement in LNG Projects, Equity Share of Oil and Gas Upstream Production.

Renewable Energy Businesses

Please refer to the ESG Data at link below for data on Renewable Energy Businesses.